|

Why a Metal Roof Cap?

Besides the benefit of this being the

crowning jewel of a classic Victorian style house or a cute gazebo;

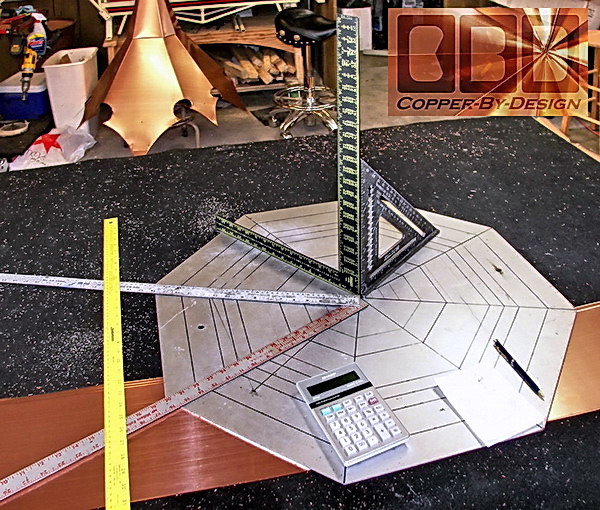

when roofing a structure like this where the roof comes to a peak with a 4, 6, 8,

12, or 16 sides it is always a problem for even the most professional

Roofer to figure out what to do at this peak to bring the roofing

shingles together; making it look right and seal the peak from rain.

Below

is some of the best roofing work I've seen, yet you can see where rain

water would still work it's way in at the top. Asphalt shingles are

easier to work with, but harder to work them into the center, where

you could have 8 layers of shingles overlapping on just a 4 sided

roof. How many layers is that on a typical 8 sided gazebo roof then?

This is where a custom sheet metal roof caps

comes in. Even if the Roofer caulked these seams at the top it would

only last a few years, and need to be cleaned and re-caulk before it

begins to fail, causing damage inside, and it is near impossible to

get caulk to stick to an aged roof. Also, this is a popular place

for birds to roost

(and poop).

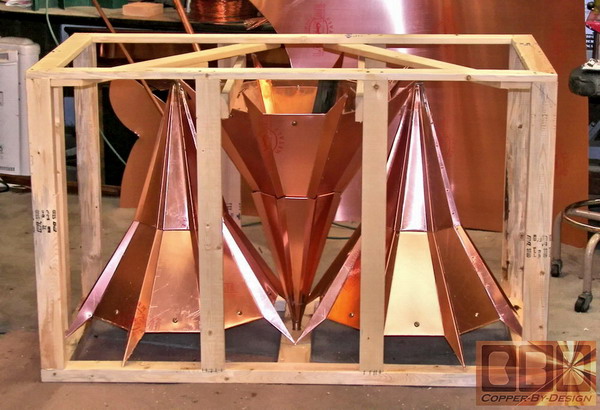

For these issues a steeper copper roof cap has proven to be the best

lasting solution to top these sort of structures, and add a nice

decorative finishing touch. For these issues a steeper copper roof cap has proven to be the best

lasting solution to top these sort of structures, and add a nice

decorative finishing touch.

Another very important issue, which is largely

overlooked for these types of roofs is venting. For some reason

venting is rarely implemented into these types of roof structures, but is

still a very important detail that needs addressed. Our copper roof caps can

be used to cover a vent hole here at the peak. We offer support

blocks and screen kit to keep out pests and give the roof cap a more

solid base to mount onto, which raises it up off the shingles. You can read more about this on our

Roof Venting web page and how we combat this

issue.

Even

if you are not considering a roof vent if it is not too late in the

construction process this hollow core center piece is what should

always be used in every turret or gazebo roof framing to attach the

roof joists onto in the middle. For some reason very few framers

know about this or have realized it's advantage this would have.

Even if they have already built the roof this can still be

implemented, but not nearly as easy to install at that point. They

will give you a fair amount of grief if you try to push for this,

but I implore you as the Homeowner to insist on it! This has nothing

to do with me trying to sell you anything here. It can be easily

made with a common 2X6 or 2X8 board trimmed at a common 22.5 degree

angle on the edges and assembled as such, and glued together. They

can hold it in place with staples until the glue sets. Simple as

that. It confounds me why this is not the standard, yet it is

extremely rare to see. Even

if you are not considering a roof vent if it is not too late in the

construction process this hollow core center piece is what should

always be used in every turret or gazebo roof framing to attach the

roof joists onto in the middle. For some reason very few framers

know about this or have realized it's advantage this would have.

Even if they have already built the roof this can still be

implemented, but not nearly as easy to install at that point. They

will give you a fair amount of grief if you try to push for this,

but I implore you as the Homeowner to insist on it! This has nothing

to do with me trying to sell you anything here. It can be easily

made with a common 2X6 or 2X8 board trimmed at a common 22.5 degree

angle on the edges and assembled as such, and glued together. They

can hold it in place with staples until the glue sets. Simple as

that. It confounds me why this is not the standard, yet it is

extremely rare to see.

Additionally,

a copper roof peak cap will help to retard the growth of moss and mildew on the

shingles below, just like zinc does. A zinc plated steel cap may

be cheaper, but the zinc coating will dissolve off within 10 to 15 years.

Then the rusty steel will permanently stain the roofing below, so copper

is clearly the best metal to use and not have to worry about it again.

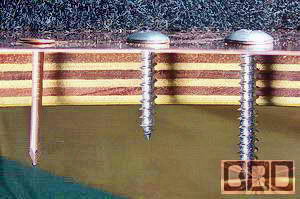

We supply the stainless steel sealing screws to fasten

these down with as well, so the copper roof cap

can be gently removed and reused when re-roofing is required, so

this cap

should be just a one-time purchase if built well.

For custom work like this and freight, the cost of the metal

used is only a small fraction of the cost, so using a cheaper metal

would only save about 10%. It seems silly to use anything less

than a good thick copper, so the cap will stand up to a century of the

elements and several re-roofings. Copper will last 5 to 10 times longer

than a steel cap, so copper is by far the best value in the long run.

Note: We

do not intend to be misleading with prices listed on these web pages

for roof caps made prior to to 2006, but as you may know metal and

fuel prices had doubled that year, so we have had to compensate. So keep

in mind how the prices listed may not reflect the current cost accurately.

They are here as a guide to see what these cost at that time. You can

go to our Latest News web page to read more

on this subject. Note: We

do not intend to be misleading with prices listed on these web pages

for roof caps made prior to to 2006, but as you may know metal and

fuel prices had doubled that year, so we have had to compensate. So keep

in mind how the prices listed may not reflect the current cost accurately.

They are here as a guide to see what these cost at that time. You can

go to our Latest News web page to read more

on this subject.

|

|

Special 'Derby Cap' style Copper Topper Offer

Ready for immediate shipment w/SS screws for just $200

delivered

This

is a small 18" wide round seamless copper dome cover, which was designed for

decorative garden

hose pots can be used for a cute roof peak cap. I discovered this can work well used to seal the peak of

a gazebo or

turret roof between a 4/12 pitch to a 10/12 angled roof. When

ordering list how many sides your roof has and what type of

shingles,

so we can punch the screw holes for you in the right places and supply

long enough stainless steel

screws w/sealing washers for attachment. These screws are

stronger than what holds your front door hinges on, so you

should not need more than 3 ot 4 screws. It is more about how

thick your shingles are.

The cost for

this w/freight is just

$200 each.

For this price I am offering these

cute finials

w/high grade 316 stainless steel sealing screws, box, packing,

and freight within the continental USA while supplies last

(just 10 left). They are less

expensive than our $300 minimum charge for

any custom work we do. With these being ready to ship there's also much less wait time

as well.

We have also use these as a decorative option

for the center

of fire pit covers we make:

http://copper-by-design.com/cw/Covers.htm

From: Mine

Date: Fri, 1 Nov 2013

Subject: Button!

I

think this looks pretty good for the money! What do you think?

It is a little hard to get a good picture because of the angles

and reflection. Your work on your website is so beautiful. I

hope we get a chance to have something made by you sometime. We

lived in Portland for a year and really loved it there.

Thanks, from Sylvia

|