|

Here is a set of 2 different angled roof caps

made for our client Marinick through Larry Wagner of

Top-Notch Construction, Inc. in Hot Springs, Arkansas. Phone #

501-627-3164. They were designed to go on the house they are

building to cover the top of the turret and gazebo built off the

back lake side of the house.

They made these very detailed plywood models to

get the right size and angle. I was blown away by how much detail

they put into these sample caps. I had never seen a client do nearly

this much before. These certainly were examples of this contractors

unusual ability to be creative.

It has the 8 wood support blocks under each

roof cap with stainless steel screening for a hidden roof vent. They

also they help give the fancy points style tails a more noticeable

look after they had tarnished.

|

|

Here is the 6 sides of this large roof cap base section drawn

out on the copper sheet and cut out with the Points style tails.

Their gazebo roof has a

lower roof pitch of 16/12, where the front turret has a 27/12 pitch

roof. I had to make several templates for these different

stages of these roof caps. I did my best to make the tails

in the right proportions given the different sizes.

Here are

the bottom section of these roof caps cut out and ready for assembly.

I had to make some octagonal pieces out of plywood to rest these on,

since the pointed tails would be far too fragile.

|

|

Here is the next sections made and attached to

the base section and holding the bottom of the finial support pipe.

I see how I should have made this section a lot steeper to make a

more noticeable transition of the angle to help simulate a curved

roof cap, but I was afraid it would make this cap too tall when I

was finished. The steeper on on the right is a good 6' tall already.

Here is some close up shots of the bonding and

sealing of the tip of these sections to the base of the finial

support pipe. I covered the clear caulk with this tape to help seal

it from the oxygen to prolong it's life span. this area should

actually never get wet, but I figure what is the harm of overkill in

every aspect of what I do?

Then I cover this with the

matching steeple cone that is riveted to the base cap through the tab

bent under the bottom edge of the steeple cone. This steeple cone also

is to hold the top of this finial support pipe in place through the

harshest wind storms.

|

|

I then added the wood support blocks and

stainless steel screen that will allow for the roof venting.

|

|

This shows the third

section in place and sealed to the top of the finial support pipe. I

had to carefully build this saddle for the first roof cap to rest on

inside the crate. It was very trick to make it angled like this so I

could try to fit both roof caps in this crate with the least amount

of space and weight of the crate for a lower shipping cost. There

boards are glued and screwed to the plywood for a sturdy ride down

to Arkansas from Oregon.

|

|

|

|

|

They are resting on a padded

stool I made, since I cannot rest it on these pointed tails. I moved

them outside to get some better shots out in the daylight. Here is

the copper Lancelot finial they wanted in hand. This is a lot of

roof cap for such a small finial, but they can still change it out

if they decide they would like to have a larger finial or

weathervane.

|

Here

is the copper roof caps both in place inside the custom crate I made

for them. the boards are glued and screwed together and then the

1/4" thick hardwood plywood sheets are attached to this frame with

the same Gorilla Glue and sheetrock screws. Here

is the copper roof caps both in place inside the custom crate I made

for them. the boards are glued and screwed together and then the

1/4" thick hardwood plywood sheets are attached to this frame with

the same Gorilla Glue and sheetrock screws.

The taller cap was set upside down in the

crate resting on the tip of the finial support pipe inside a wood

block with a 1" hole cut in it. This shows how strong I build these

support pipes that the full weight of this cap is held securely

bumping down 2,000 miles of road they need to travel. I built a

padded saddle for this upside down cap as well secured to the roof

of the crate, so this cap will not move sideways in the crate and

bend up the points tails. I understand it did reach it's destination

without harm.

|

|

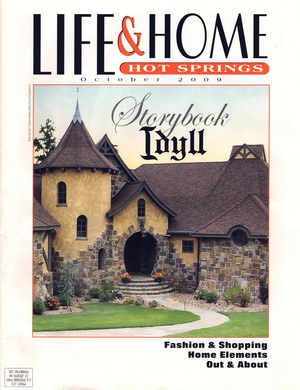

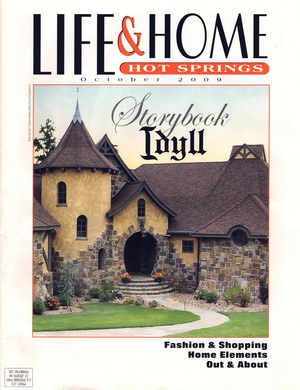

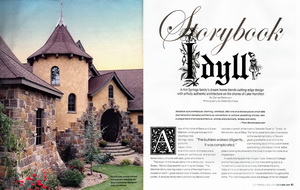

Here is these turret

roofs mounted in all their glory in these photos sent in 12/08.

This is a really neat house being built

on the shore of a lake in Hot

Springs Arkansas designed with these complex curved roof lines.

The final

weights for the taller cap is 43.4# and the shorter one is 34.2# =

77.6#

77.6# - 10.8# for the wood blocks, screening and screws =

66.8# copper weight

66.8 X .8 = 53.44 sq' X $50 = $2,672

It is

not a lot less than the original quote, but it did shave off about

$40.

$2,672 for the copper

+ $250 for the finial support

pipes built into the roof cap

+ $340 for the pair of Lancelot

finials w/15% discount for buying w/roof caps

+ $140 for wood

support blocks w/SS screening for a hidden roof venting

$3,402 total cost of this set delivered less the $2,000 deposit =

$1,402 balance

|

Cover page:

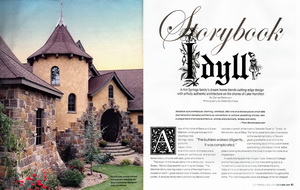

First & Second page:

Third &

Fourth page:

|

Here is some

shots out of the magazine article that featured the amazing work on

this house.

They were kind enough to mail me a copy.

Fifth page:

Sixth page:

|