|

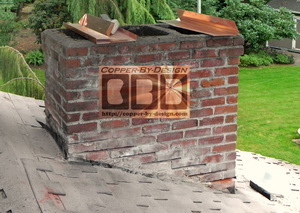

From what I have seen chimney flashing is

the most neglected area of a roof, if re-flashed at all. That is why

this is such and important detail that you need to be aware of. More

times than not it wasn't re-flashed during the last re-roof, which

is against minimum Building Code. Here in Oregon they recently

changed Building Code to indlude a cricket when ever reroofing is

done, yet it is still rarely added to the job, since most homeowners

do not know of this change to the code. Now you know.

Why a 2-Part Flashing is Needed with any Brick Chimney:

Chimney flashing needs a

2-piece; a step-flashing mounted on the roof deck integrated with

the shingles, and a separate counter-flashing piece that is mortared

into the gap between the bricks. NEVER cut into the brick! This

2-part system to allow for the movement of clay structure of the

chimney and the wood structure surrounding it, caused by expansion and contraction

as temperatures change throughout the day, and throughout the

seasons from below zero to possibly 120 degrees. Also, as you heat up the chimney while in use.

The step-flashing gets nailed on the

roof and lays up against the side of the chimney. Then the

counter-flashing is mortared in the chimney (NEVER caulked) to hang down over the

step-flashing to maintain a water tight seal, yet allow for this movement.

This is why caulking this flashing is futile and will separate before

long. If it is flashed properly, there should be no need to caulk it

at all. Even in the corners. It needs to maintain this seal even

with wind-driven rain and snow.

If you see black tar smeared on your

roof, that is only a desperate temporary fix at best, and needs to

be remedied quickly with proper rust-free flashing.

Common Problems

With Roof Flashing:

Clearly the #1

cause of roof failure is faulty and or rusted out steel flashing; either from improperly

installed, or complete lack there of, which I have seen all too

often. If there is caulk on your roof that's

usually a sign of a temporary leak repair and needs properly dealt

with as soon as possible!

In my

3 decades of experience crawling up on several thousand roofs, seeing

these details up close, I've seen how in most cases

the Roofing Contractors did not re-flash many of these problem areas,

which

they were hired to fix in the first place. Let alone flashed the

right way. Leaving the worse problem areas of your roof not resolved,

so

you've just been cheated out of thousands of dollars and made to

suffer continuing stress. That's like

having your car repainted without even washing your car first, or neglecting to

sand the rusty areas for the paint to stick to a good

clean solid surface. Resulting in the paint starting to peal off the

first time you run it through the Car Wash.

I've done several tear-offs where I removed 2 layers of composite shingles

over

the bottom layer of wood shakes; in where the only flashing I found

around the dormer was under the wood shakes, and of course it was

very rusty and deteriorated. That means the last 2 Roofers had not bother to re-flash their

dormer at all. I have yet to see evidence of a decent Roofer

in this area (no joke). It really is that bad!

This means you are

99% at risk of being ripped off by any Roofing Contractor you're

likely to encounter, so I have added this educational information to

help arm you while interviewing potential Roofers. Since I do not

sell roofing work, this infor is honest and unbias.

One of the problems stem from sheer

ignorance, ethics, and lack of good examples to follow. Roofers come more from a hammer and nail

Framer mind-set. Not from a

sheet metal worker's perspective like me, so these areas of roofing escapes

their private logic and confound them on how to manage wind driven

rain, which all roofs will encounter.

Sadly ethical responsibility seems

to be a thing of the past. I understand this is not just a local

issue either. Improper roof flashing using

just cheap

steel is the standard across the Nation. This thin steel flashing

will not even last as long as the most inexpensive low life-span 25 year shingles. Even if it does not rust all the way through it will cause

unsightly rust stains down the roof, as seen in these photos.

To see more photos of this project click

the link below

http://copper-by-design.com/rf/Viges.htm

I have personally seen thousands of

examples of this close-up. In most cases they will just bend the

old counter-flashing out and slip the new step-flashing under it, and

then just bend that rusty counter-flashing back down over it. When I've

gone out of my way to question Roofers about this they say it is the

job of a Mason to replace that flashing. This might be OK if a Mason

was called out to do it. Or, at least make sure the Homeowners was

made aware this roof job is

not yet finished, and they need to call in a Mason to finish their

work. I have come to learn most Masons do not know how to replace

this flashing either, and really don't want to be bothered with it.

It's way too much work and not worth their time to even bid such a

small and dangerous job, so you as the Homeowner are left with no options.

How does this make any sense?

Even if this flashing is not rusty at all, it is not

going to last through the life-span of the new roof. Even though Roofers

are not willing to replace old flashing

they are not likely to bother notifying you the Homeowner of these rust

issues that still need fixed, so you don't have a clue that the

roofing job was never finished. Then you'll start to notice staining inside from

those leaks, which means

serious damage has already occurred.

What's worse with this scenario is how many Homeowners are conned into paying to fully re-roofing

their house because of these flashing leaks, instead of just

replacing that flashing. These fancy talking Salesman are much more

motivated to sell a whole re-roofing package to unsuspecting Homeowners

to make that big ticket sale. All the while, knowing they have no intention

to replace that defective flashing with something better.

Even if they do actually replace

that flashing, they again will do this new work without the benefit

of using a rust-free metal like aluminum or copper. Keep in mind how

in most cases they will not bother to re-flash the problem areas

as they had promised; failing to solve your

actual problems.

This is the main reasons liability insurance

for Roofers has been very hard to get and extremely costly for

several decades. Costing around 500% more than any other type of construction work.

That is very telling in of itself; demonstrating irrefutable proof of what I'm

saying here. Numbers don't lie. Feel free to research this.

Most of roof flashing can be replaced without

re-roofing the whole house (as seen above), but of course that is far less profitable

for a Roofing Contractor, so that option is rarely discussed or considered as an option.

Each one of those Roofers know better, but they still do

the same kind of crapy roofing work with that same cheap steel flashing, which they

just tore off of your house. Seeing the evidence of it's failure

time and time again.

They all know how the new flashing will fail in short

order, but they just don't care. Isn't this said to be the definition of insanity: doing the

same thing and expecting different results. Sadder yet is how they

are only saving not more than $300 on the average reroofing by not using

all aluminum flashing; which is about twice as thick and will not rust even if all

the paint were to flake off decades later and still protect your

house.

It's criminal in my mind. Can you imagine the amount of

landfill that could be reduced if steel flashing was made illegal?

Yet for over 30 years that I know of; Roofing Suppliers are not allowed to

stock aluminum, stainless steel, or copper flashing by their

Corporate Office.

If that were not bad enough; Instead of flashing

areas with metal; they will often use the cheapest caulking sold; called mastic

or asphalt tar.

They just smear it around those problem areas. Mastic is just fibered tar with

no UV protection. This will usually get the roof past their minimum

required 1 year warranty the Construction Contractors Boards requires

of any Licensed Contractor, but not lasting much more than that. Mastic

will become brittle, crack, and peal away within a few years. If

their work were to be inspected by a State Code Enforcement

Inspector it would not be approved. They are not to use mastic

anywhere on a roof. That is a clear sign this roof was not properly

flashed right. Mastic is only to be used as an emergency patch to pacify

the leak until a proper fix can be made. Although, it makes for a very messy

clean-up when that repair can be done. The roofing in that area has to be replace after a mastic attack, as

seen in these photos:

To see more photos of aluminum flashing

click the link below

http://copper-by-design.com/rf/Alum.htm

We know this to be a very common intentional crime of

Roofing Contractors, since pretty much any roofer has seen the

evidence of these

all too common issues when doing a tear-off of an old roof;

i.e. very rusty steel flashing on the roof and mastic failure with

stained plywood underneath. When they tear into

a bad roof for replacement it tells a story: why this roof failed.

They would have to be complete morons to not see this clear evidence in front

of their eyes.

Yet, they continue to ignore this evidence and do

the same shoddy work, since in most cases they are not required to file for a

building permit to replace your roof year after year; not having to worry

about an inspector double checking their work. It has been this way

for over 3 decades that I know of. If more than 15% of the roof deck

needs replaced a Roofer is required to file for a permit. Yet that

is still rarely done, since they know their work will not withstand

the scrutiny of an inspection and you are the victim of this

negligence.

What about Lead Flashing?

Some clients have asked about using lead for chimney flashing.

Roofers like it, since they can cut is so easily with a box-cutter

and form it by hand. It is some times use while the chimney is being first built, but I do

not know how you could be able to get it into the mortar, when the

more rigid and thinner copper flashing is difficult to quickly

install before the mortar sets.

Another important issue with lead is how

soft it is. I have seen numerous cases where animals had chewed

holes in lead flashing.

My understanding is lead is harmful to the environment and people as well, so lead is ill advised.

That is why they made lead illegal to use in gasoline almost 50

years ago.

Common signs of shoddy workmanship:

The most common mistake I see Roofers make when they have bothered to re-flash a chimney is to cut a shallow groove

along the diagonal sides of the chimney to caulk a straight piece of

flashing in, but these will not remain attached for long to the crumbly bricks and

old mortar. Although that is not the worst problem; this sets up a

fracture point for the chimney to crack and possible collapse in a

minor

Earth tremor. I have seen lots of evidence of this happening. So,

keep in mind how if

they do this to your chimney, they have permanently damaged your

chimney. Where the only solution would be to rebuild the chimney

down to the roof line with new bricks. If this damage has not yet been done

to your chimney you need to warn your Roofer how you will require

them to rebuild your chimney if they do this.

Shown in these photos below I was able to

easily pull the long side flashing piece off without straining. Let

alone the need for tools to pry it off. That is an example of how

poor this sort of fix is. This was not an old install either. It was

done less than 2 years prior to my replacement work.

To see 12 more photos of this project

click the link below

http://copper-by-design.com/rf/Bassett.htm

Even high quality silicone caulk should never be used to

attach counter-flashing, because it is just rubbery and adds no structural

strength to your compromised chimney. Just as with the useless effort of tuck-pointing

a chimney to make the mortar grooves look nice again; the new

granulated caulk

in such a shallow groove has only the old crumbling mortar to stick

to, so it will simply fall out within a few years. These grooves

need to be ground out a lot deeper than just 1/2" in order to

have the upper and lower brick surface to adhere to, and only be filled back in with

REAL mortar. The groove

needs to be at least 1.5" to 2" deep. Anything short of that

is a waste of time and money.

Aluminum flashing can be special ordered

from a fabrication shop like mine, but of course that makes it just

much more expensive than mass produced stock, but the time delay is

the main reason roofers will not have it made for your house. If you

bothered to have aluminum flashing listed int he contract, 9 times

out of 10 they will still show up with steel flashing parts. If you

are not there with a magnet to test and demand they get the right

flshing, you just got screwed!

My Roofing web page at:

http://dmr-gutters.com/rf/roofs.htm

goes into more detail about these terrible issue. So don't

leave without reading it over. It will help to save yourself a great deal of

wasted cost and anguish

down the road.

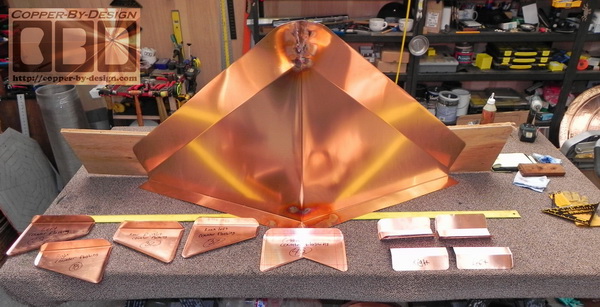

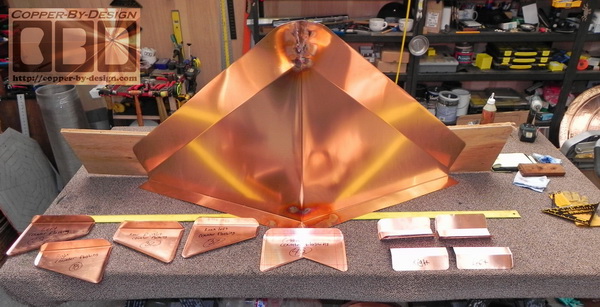

Can you make us a custom copper chimney flashing kit?

Here is an example

of one of my first Client installed chimney flashing kits back in

2008:

I seem to be the only sheet metal shop willing to spend the time to work

with Homeowners through e-mail to figure out these custom kits for

them or their local installer to use. They are labeled and numbered

in order of installation, precut, and bent to minimize

customization needed at the job site. Below is some instruction and

detailed photos to help give you a good idea of how to do this

properly.

For more information regarding custom

chimney flashing kits I make for our Clients across the Nation go to my Flashing

Kits web page for

more details:

http://copper-by-design.com/rf/cf-kits.htm

What about chimney flue pipe flange and

other flashing?

As you can see from our web

site I can also help with many other custom flashing needs. Although,

you may need to consider physical contact of the copper flashing

with steel pipes and the detrimental effect it will have on the

steel through electrolysis or galvanic corrosion. The steel will not harm the copper, but

the copper will accelerate the deterioration of the steel. Stainless

steel is compatible with copper. This chimney pipe for a wood

stove in my wood shop corroded within a year and became unusable.

What If

I Already Have This Kind Of Shoddy Workmanship On My House?

If you are are a victim of this all too common unethical business practice

you can show your Contractor this web site. Then you should be able

to deduct the cost of repairing your chimney and it's flashing even

if you are going to do it yourself, plus the cost of cleaning off

that black tar. I would encourage you to insist he has that tar

removed and cleaned off by his workers to the point as if it were never there.

That ought to teach him a lesson. It is messy work

and solvents on your new roofing will damage the shingles and cause a terrible

staining mess. If the contractor uses a solvent he'll then need to replace

all the damaged and stained shingles at the same time.

Do not let them talk you into any other

alternative, trying to minimize their costs. They will try to

discredit me and say I do not know what I am talking about, but it

is simple logic here they cannot BS their way out of if you stand your ground. Roofers will

claim that it can only be done this way when the chimney was first built

by the brick mason, but I prove here that is simply not true.

Below are examples of jobs I've worked

on, that show these shoddy practices I've worked to repair.

Are there any other flashing shapes that

may be better?

In my effort to seek a better product for my

clients I had designed a special type of

step-flashing with a pair of 45 degree bends, in stead of just a

single 90

degree bend. This is an improvement over the standard right angle

bend configuration normally used. This has several advantages and

should not be difficult to fit into any type of roofing material.

Here are a pair of photos of this

alternative flashing being

installed by one of our clients:

Sealing around the corners of a chimney has always

presented a problem to make sure it's water tight without the use of

a caulk, which could fail sooner than the life span of the roof. It

needs to maintain a seal even in the harshest wind storms and allow

for the expansion and contraction with will differ than the wood

structure. I have

found this alternative shape helps in several other ways as well:

(a) navigates the rain water out away

from the corners of the chimney a bit better.

(b) slows the water down and reduces

upward splattering under the counter flashing.

(c) helps to be able to trim off the

commonly compromised and damaged shingles nearest the chimney when

replacing the flashing without a full re-roofing project, thus reducing the shingles needing replaced around the chimney.

(d) helps reduce scraping needed

where the chimney meets the roof: old caulk or sloppy mortar work.

(e) makes it easier to cut the new

grooves without needing to grind so close the the roof.

(f) application of an underlayment resting

up against the side of the chimney for added protection is also made possible;

without such risk of cracking that membrane needed with conventional

flashing with such a sharp bend profile.

To see more photos of this installation

follow this link:

http://copper-by-design.com/rf/Druschel.htm

Let me know if you need any special

configuration and we'll customize your kit to fit.

|