|

Cap Sizing &

Designing:

Of course

we are happy to build you a cap as large and as ornate as you wish,

but we are plenty busy with orders, so I am not out to up-sell you. Our focus is on you're

long term satisfaction with the size, quality,

and price of our caps. One of the best ways to figure out the right

size is to make a full size cover with inexpensive and easy to work

with materials. Like left over roofing felt, or cardboard. This way

you can stand back a ways to get a better feel for how this will

look. Then you can decide if it should be a little larger or smaller

than the cover you had just made. Simply cut a circle in that flat

material. Then cut one line from the outer edge into the center.

From there you can overlap this seam to form a cone shape that will

conform to your roof angle.

Temporary Roof Cap:

I understand how

many had not planned ahead and may not have the time to wait for our

custom cap to arrive,

so if you are concerned about sealing the roof peak until the new roof

cap arrives and is installed; for not just have the roof shingled up near the top

where the shingles begin to converge. Then use some roofing felt cut in a large circle

(as described above). Without even cutting the roofing felt it can

be fold on one side to overlap up to the center point to form into a cone shape

to make a temporary cap which will then cover the top of your roof. Tape the

fold together and tack it in place on the roof peak. It can also give

you a better idea of what size cap would look best up there. This will

relieve the pressure to make a hasty decision of what sort of roof

cap would be best, a finial or weathervane added, and whom you should

do business with.

Sizing:

If you are having

any trouble visualizing what to ask us to fabricate in copper sheet

metal for you, you are not alone. We get asked what size we advise quite

often. As a general rule; you can take the width of the roof at

the base. For example; if your roof is 12' wide, you can divide

it by 1/6th to get a medium size range. Or divide by 4 to get a

large size cap. Although, if this is for a gazebo roof that is lower

to the ground, you can divided by 8 to get a cap that is on

the small size.

If it were a gazebo roof, people commonly lean

toward the medium to small size, depending on how ornate they are looking

to go. On a turret roof for their house, people commonly lean towards

the medium to large range, since it is usually on a second story roof,

which will make the cap look that much smaller from the ground, where it will

be seen most. We hope this helps you figure out what is the best

size for your roof.

To recap our sizing guide:

1/4th scale of

your roof size = a large size roof cap

1/6th scale = a

medium size roof cap

1/8th scale = a

small size cap

You are welcome to consider any variant in size between these

numbers it calculates to, but this is just to help narrow the

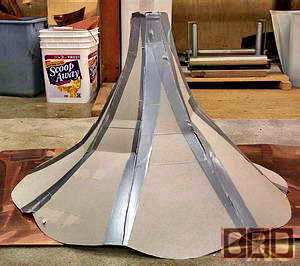

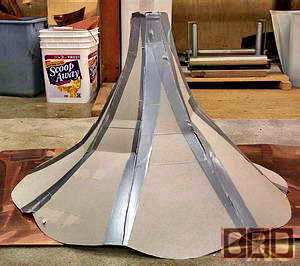

parameters. As you can see in this photo it would have looked odd if

i had made this pair of roof caps the same size for these two

different size turrets.

We

wish we had more photos of caps in place on the roofs of our clients

to show you, but even though many clients say they will send us a picture

of their new cap after installation, it is rare that that we hear

from them again, and I am not the kind of company to pester our Clients for those

images they had promised. We

wish we had more photos of caps in place on the roofs of our clients

to show you, but even though many clients say they will send us a picture

of their new cap after installation, it is rare that that we hear

from them again, and I am not the kind of company to pester our Clients for those

images they had promised.

This house happened to be near enough

(150 miles away) for me to get this photo

(shown right). The roof caps shown here are

just a medium sized to the roof below. Even though it seems over

whelming there on the ground before installation (shown up above),

after installation this Clients said he felt

they were definitely not too large, as you see here.

To experiment with different size options, a

small scale model of

the roof may help a little, but it does not clearly represent how it

will look from the ground of the real roof top. So to build a simple

life-size prototype of a roof cap will help this process immensely,

since once I make this in copper the size will be set for life:

(a)

Get some cardboard to cut up for a sample cap. To first get the

dimensions for the cardboard; you can use a rope or string to place it in

a circle near the top of the roof around where you think you would like the

bottom edge of the cap to be. Write down the measurement from that

rope, and the measurement up to the peak of the roof as well. Divide the

rope

length by the number of sides of your roof. This will give your the

width of each triangle. (a)

Get some cardboard to cut up for a sample cap. To first get the

dimensions for the cardboard; you can use a rope or string to place it in

a circle near the top of the roof around where you think you would like the

bottom edge of the cap to be. Write down the measurement from that

rope, and the measurement up to the peak of the roof as well. Divide the

rope

length by the number of sides of your roof. This will give your the

width of each triangle.

(b)

Draw out one of these triangles on a sheet of paper and cut it out to

use as a template to draw it out on the cardboard. Cut and tape those sections

together in the shape of the cap, like shown in the photo to the right.

(c)

For simplicity, you could just roll the cardboard together in

one large cone shape taped or stapled together, and then cut the bottom

edge off in a circle at the same distance from the center point.

(d)

Set this prototype up on the roof top and look at it from a distance

to get an idea how

one of our copper caps might look. You can then get a much better idea

if you want it any larger or smaller than your prototype, or other details like the angle

or height.

(e)

From there you will be ready to tell me what the dimension is

of the cap you want CBD to make for you, so I can quickly quote you

an exact price to fabricate it just the way you want.

|