|

This is a pair of copper

caps for John Jessum in Sammamish, Washington for their front circular

and rear 12 sided turrets on their house. This shows the aluminum template

I made to draw out the base section. I was able to form 12 sides in

one piece and the other overlapping 4 sided back section in the other

piece.

|

|

This

shows the base section bent into shape with raised corners for a dynamic

look and adds strength incase of an impact from falling branches flying

through the air in a wind storm. I had attached it to the back 4 side

piece.

Then I added braces at the bottom of the raised corners to make sure

they will not spread open wider and change the 21/12 pitch angle of

the roof cap. It took 16 small scrap pieces with 4 rivets each = 64

rivets. There are already about 100 rivets in this.

|

|

I had left the center section

out of the base since it would be too hard to make all these bends on

such a large piece up to the center. It is better to make a more simple

16 sided center cap that is riveted over the top of the base. It will

not be seen once finished and offers a flange to attach the steeple

cone on to, which maintains the best possible weather seal and also

offers some added roof venting up higher inside the roof cap. This center

cone supports the bottom of the finial support pipe. It took another

80 rivets for this part.

|

|

The first photo below shows the steeple cone partially

formed with the base section in the background that has been caulked

over the solder and rivets to make certain they will never leak. I then

covered the caulk with a special tape to shield it from oxygen to increase

it's life span.

The left photo shows the steeple cone attached

and sealed at the top with a copper plumbing pipe reducer to cover the

top of the steeple cone and soldered in place to hold the top of the

finial support pipe in place to have a strong hold for the next century

of stormy weather. There is another 48 rivets holding this on, so we

are at about 250 rivets so far in this one roof cap.

|

|

|

|

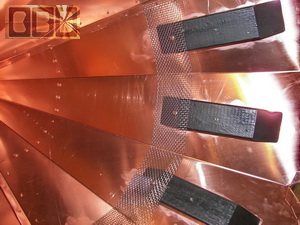

The underside shot shows the wood blocks in place

with the stainless steel screen attached with 16 stainless steel screws.

The underside has been recaulked over the seams and rivets. I switched

to using the stainless steel screen since it is stronger than the copper

gutter screen I was using, and has a smaller hole spacing as well. All

the screw holes in the blocks were pre-drilled, so they will not crack

and split.

|

|

The Rear 12 Sided Turret Roof Cap Fabrication: |

|

This is the very first 12 sided roof cap I have

been asked to make. I had not even received a request for a quote on

a roof cap like this. Here is

the 3 sections of 4 sides each for the back turret roof cap base. I

was only able to form 4 sides in one piece for this roof cap. I could

not even make this with a 5 sided piece

from the 3' x 10' sheets I use. This one was designed to fit a 24/12

pitch roof peak. The photo on the left shows the 3 sections bent into

shape just before sealing them together.

|

|

Here is the base attached together and sealed

with the finial support pipe sealed to the tip. I always am careful

to have the cap base on a level surface and make sure the pipe is set

perfectly vertical before soldering and riveting it in place.

Then there is the forming

of the steeple cone to cover this and hold the top of this pipe. This

steeple cone is about as steep as they get. It was 16" wide at the bottom.

I made it to have 2 of the 12 sides overlap, caulked and riveted together

with this bottom flange bent under for the hidden attachment to the

base section.

|

|

|

|

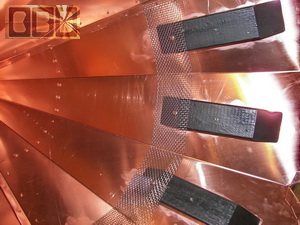

This shows the set of 12 blocks for the

hidden screened roof vent.

These black painted wood blocks were made to be used as spacers for

venting the roof under the caps, as well as giving the roof cap bottom

design edges a better visual distinction than if they were to just lay

flat on the roofing.

I

mounted the spacer blocks inside the cap base to suspend it 1.5" out

over the roofing shingles and attached the screen to sealed out pests

that may want to nest inside these caps. The blocks were primed

and painted with a high quality black paint, so they would not be visible

from the ground.

Each block has a pair of holes drilled and counter sunk for the 3" deck

screws to lock them to the roof.

|

|

The final cost with the

53" Morgana and the 39" Fluer De Lis finials was $3,157.50 without a

crate and shipping, since the client lives close enough to come here

to get them. He saved $82.50 from this for the added copper I used over

the quoted price.

|

|

Here are the

finished turret roof caps, side by side along with the finials he had

ordered. I brought them out in the day light to get a better photo:

Here are my clients picking

up their roof caps and finials in the boxes to the left

These are the photos they

sent of these turret roof caps mounted

They agree the new 1/6th scale

roof caps do not look too large once mounted 3 stories high

From: "john jessum" <jjessum@gmail.c*m>

Date: Fri, 18 Jul 2008

Subject: Re: pictures for you

Finally got them up! Will let

them set and screw down Sunday.... Didn't put the

Fleur up yet but will Sunday. Enjoy! Thanks again

for everything! The guy who helped me is building

a turret on his own house so me thinks he will be

contacting you shortly about a cap for him.

Date: Sat, 19 Jul 2008

I agree, they don't

look too big now that they are up. I

think the larger draw to the eye is

the shininess of them, but that will

mute with time as they go patina I'm

sure. I hope the glue sticks as I did

not notice any "foaming" after I applied

it to the blocks, and the one syringe

did prove to be a little short, so I

applied silcone caulk to the others,

hoping that when I lift the cap tomorrow,

there is some adhesion there. Alright,

on with the day. As I mentioned the

wife is wanting me to get some extra

time out of that lift by washing the

second story windows!

Date: Mon, 21 Jul 2008

Ok, both are officially up and secured

into place!!!! A couple of notes. There weren't enough of

the brown screws to match all of the blocks and holes so

we had to make due for about 5 blocks with just one as we

were way up there and didn't much want to come down and

go back up. I think at that point my friend and I were thinking,

"this sucker ain't going no where!"

Drilling the roof vents was not too bad

except by the last one the hole saw was pretty dull from

ripping through the composition shingle. My brother-in-law

from the East Coast, who was unwilling to go up on the lift

thought I should be featured in an episode of "extreme homeowner!"

I don't like much heights, but by the end of the day I was

pretty comfortable up there and able to maneuver that machine

within inches. I think every homeowner should have one.

I was able to get a fair amount of windows taken care of

plus a good gutter scrubbing.

I think you should tell others to go

up with a drill bit as well as the blocks can shift somewhat

making hole alignment difficult and with a drill bit one

can pre drill holes as need be, but all in all the process

went smoothly and I was fortunate that we could approach

both sides of the house on flat ground. My front lawn does

have some tire ruts but hopefully in time they will fade

out.

Let me know if you want more pics. Next

year I think we will try for the chimney cap!

Be well.

Jess

|