|

Here is the photo of their gazebo they had

built just off the house porch integrated into the house roof. They

wanted one of my nice copper roof caps and Avalon finial made for

our client James Meyers in Machipongo, Virginia. He reported their

gazebo roof has a 14.5/12 pitch, so I built the roof cap to be 16/12

pitch to make sure the bottom edges would sit flat on the roofing.

This roof is 14' wide, so at 1/6 scale this cap is to be 28" wide

plus the tails below that, and this is what I made them.

For some reason I had it in my head that he

wanted the Points style tails and had been sending them photos of

the step-by-step progress you see below. He never said a word. When

it was complete and I was writing up the invoice with the price

adjustment; I saw how I was way off from the estimated weight. That

is when I discovered this mistake. I had to ask him what we should

do about this, besides how this would also require a much lager

crate, which means higher shipping charges as well. He was OK with

me sending this cap to them, but was unwilling to split the $400

difference in cost, so I had to start from scratch and make him a

new roof cap like he had ordered.

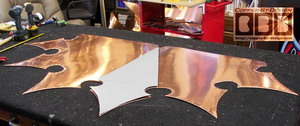

It was a shame, since as you can see in these

photos this was the first set of Points style tails I had done with

a safety hem all along the bottom edges. Above is the 6 sides of 8

for this large roof cap base section drawn out on the copper sheet

and cut out with the Points style tails.

This roof cap is available for quick sale at 20% off if

it happens to fit your needs (finial sold seperately).

|

|

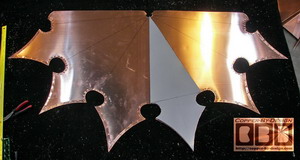

Here is the Soft Scallop style tails copper

roof cap they had ordered being built. Since the tails were a lot

shorter I was able to get all 8 sides in one piece, so there is only

this one single seam to seal and rivet together.

|

|

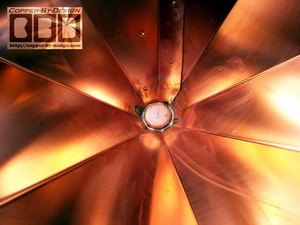

Here is this sections attached to

the bottom of the finial support pipe.

Here is some close up shots of the bonding and

sealing of the tip of these sections to the base of the finial

support pipe. I covered the clear caulk with this tape to help seal

it from the oxygen to prolong it's life span. this area should

actually never get wet, but I figure what is the harm of overkill in

every aspect of what I do.

Then I cover this with

the matching steeple cone that is riveted to the base cap through

the tab bent under the bottom edge of the steeple cone. This steeple

cone also is to hold the top of this finial support pipe in place

through the harshest wind storms.

|

|

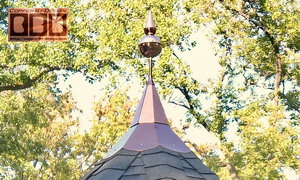

After finishing this I moved them outside to get some better shots out in the daylight.

Here is the copper Avalon finial they wanted set in place. They can still

easily change

it out for a different finial or

weathervane they like better.

|

Here is the copper roof cap in place

on the base of the custom crate I made for it. The boards are glued and

screwed together and then the 1/4" thick hardwood plywood sheets are

attached to this frame with the same Gorilla Glue and sheetrock

screws.

|

|

The finished product 1.

|

Here are the 14 photos they sent in 9/18/08

of the installation.

1st fit check - a perfect fit. |

Checking level using finial rod. |

Checking the fit from ground view.

|

Scribing alignment marks after leveling. |

Drilling

the pilot holes for the SS screws. Drilling

the pilot holes for the SS screws.

|

Using an awl in drilled holes to maintain alignment. |

Starting caulking process - white caulk turns clear when set. |

Fastening the cap down using SS screws. |

Polishing the finial ball before installation.

|

Removing the clear protective film 1.

|

Removing the clear protective film 2.

|

|

Installing the finial ball.

|

|

The

final weights for ths cap is 17.2# X .8 = 13.76 sq' X $50 =

$688. This was still more than the original quote, so there was no

discount, but they did get $68 worth of free copper/shipping. The

final weights for ths cap is 17.2# X .8 = 13.76 sq' X $50 =

$688. This was still more than the original quote, so there was no

discount, but they did get $68 worth of free copper/shipping.

$620 for the copper

+ $125 for the finial support pipe built

inside

+ $170 for the 22" Avelon finial w/15% discount

$915 total cost of this set delivered less the $457.50 deposit =

$457.50 balance

|