|

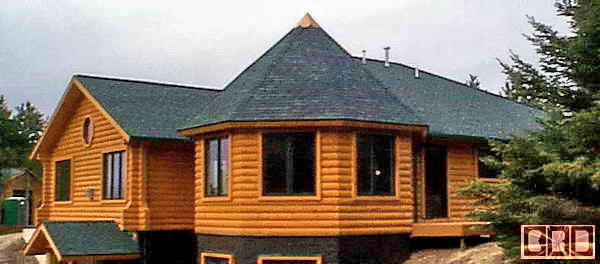

This large solid 20oz copper

roof cap was custom made (10-04)

for, Chuck and Cynthia McLaughlin in

Interlochen, Michigan. We received

the needed info from them in their first letter and were able to lock

down the details of this cap in a single reply, so they qualified for

the 5% discount, down from $386 to $365.75 for this 11sq. feet cap at

$35 per square feet of copper needed to build this cap. It has

the half round scallop tails with a safety hem bent under along that

edge.

|

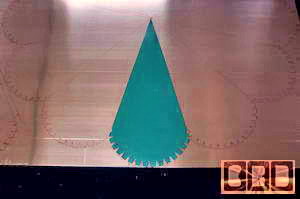

The sheet of copper shown above is 10' long

and 3 feet wide, and still has the clear plastic film over one side

that will be used for the outside of this copper roof cap to protect

it from finger prints that make an uneven tarnished look. Next

to that picture shows the template for one of the 8 sides that we made

from the dimensions given for this cap. The cuts in the bottom

curved edge is for the cuts we need to make for the safety hem.

We have the cut and fold lines for this cap drawn out on the copper

in red. Because of the size, we could not make it in one piece,

as we try to do, so we had to cut the 8th side out in a separate piece.

|

|

This is the roof the cap sections

cut out in the large copper sheet. This may not the most practical

use of copper sheet metal, but this way it is much less likely to develop

a leak, and it is much stronger this way.

Next to that is the notches

cut out for the safety hem fold over. They are to be folded over

for a safety hem on the leading edge, as you will see in the next photos.

|

|

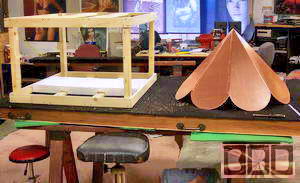

The tabs are cut along the

bottom edge of the scallop design they asked for and folded over to

help strengthen it and make it easier to handle. It also resist any

possibility that a strong wind could rip at the copper and dislocate

the cap.

The next photo shows three sides bent to form the

cone cap shape.

|

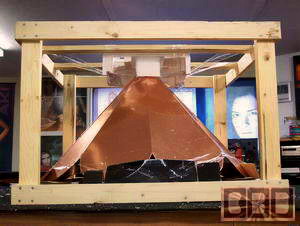

| These pictures show this cap

bent into shape, but the cap is not yet sealed and riveted together

in the cone shape, showing the 2 seams we need to seal.

The second picture shows the cap riveted and sealed

with some special black cloth gaffers tape over the extra bead of caulk.

|

|

This shows the cap sealed and riveted together. The first

picture on the left shows the 2 riveted seams that will be placed on

the back side of the turret for the cleanest look. You can click

on the pictures to get a better look at the over-lapped riveted seams.

The second picture shows the side that will be seen most.

Again, it still has a clear plastic film over the bare copper

to help keep finger prints off the copper. The oil from finger

prints causes early tarnishing and makes it tarnish in a rather spotty

manner. The plastic film will be pealed off after the final installation.

|

| This is showing the wood frame supports for the

custom crate we make special for each cap. This process takes almost

as much time as making a simple cap like this

The second picture shows a side-by-side relation

to the cap and the crate. We have the first Styrofoam sheet cut

and set in place.

|

|

Here is a close-up of the crate. We glued

the boards together here, and predrilled the holes before nailing to

insure the wood would not crack and split.

The second picture shows the cap set inside the crate

over the 4 pieces of 2" Styrofoam.

|

|

Here is a close-up of the crate underside.

There is clear packaging tape suspending the top of the cap in place

with a special piece of Styrofoam over the tip to protect it.

|

|

Here is a close-up of the crate under the cap, showing

the tube of caulk supplied. There is also a zip-lock bag with

the 8 + 2 spare stainless steel screws

and a new #3 Phillips tip to fasten

the cap to the roof.

|

|

We cover this wood frame with

cardboard using a staple gun, leaving an inspection hatch, so the shipper

can see we are not smuggling contraband. We then use a hand stapler

to seal the crate with the last cardboard side. We marked the cardboard

with a 'Top' side, so the shipper knows which side would be best during

transit.

We sent the client these digital

photos of the progress to get their feedback of what they think of this,

and if they have any ideas or concerns. In this case we were able

to get it all done by working a full day on it and getting it off to

the shipper the next morning, but we had been in contact about these

details and knew we were in sync.

|

|

Detailed

Installation Instructions:

It is not very

complicated, but here are some suggestions.

1. Place the copper cap

on the roof with the seams of the cap to the back side, and press it

down tight.

2. When you have it set in place, mark the holes for

the screws with a narrow pen or fine tip magic marker or even an ice

pick to pre-drill the holes with an 1/8" drill bit. That will let the

screws go in easier and less likely to strip out the head. You could

leave the cap in place while drilling, but it most likely will shift,

messing up your alignment

3. You may want to add a line of caulk

near the bottom edge of the cap to seal out insects from nesting inside

the cap.

5. The cap will go on the roof using the dome head #3 Phillips

stainless screws. Line up the holes and screw it to the roof with that

one riveted seam to the rear of where the cap will be seen most.

|