|

Here

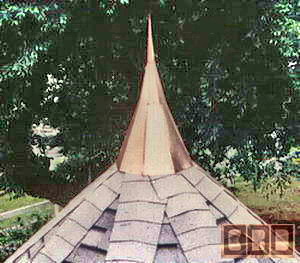

is one of the first copper gazebo roof caps I made several years back

for a large eight sided entry porch roof built onto the front of a house

in Boring, Oregon, just South-East of Portland. We did this in

conjunction with the gutter replacement and some vinyl soffit work they

asked me to perform. This cap alone stands about 4. 5' tall and 2' wide

at the base. I had decided to give this cap a steeple look and

the customer was pleased with the results. Here

is one of the first copper gazebo roof caps I made several years back

for a large eight sided entry porch roof built onto the front of a house

in Boring, Oregon, just South-East of Portland. We did this in

conjunction with the gutter replacement and some vinyl soffit work they

asked me to perform. This cap alone stands about 4. 5' tall and 2' wide

at the base. I had decided to give this cap a steeple look and

the customer was pleased with the results.

Although, looking back it is a bit of an embarrassment

to me now. In order to save copper here I cut

these 17 separate pieces and sealed them together.

We since feel that it is best to do what we can to minimize the number

of seams for better looks, strength, and far less chance of it leaking

a century later. It is also far too time consuming to seal and

rivet all these seams together, and is simply not worth the copper sheet

metal we saved to do it that way. We also use a lot more rivets

along the seams that I do need to seal, for better strength. More like

good aircraft construction.

It took about 16 square

feet of copper sheet metal to form this roof cap.

The cost of this back in 1999

was around $350 installed. They got a

good deal, but it was the first large roof cap we had made. We now do

our design and fabrication a lot differently, and use a thicker copper

sheet metal as well. Also copper has doubled in cost since then.

In hind-sight:

If I were to put the same labor into this, in sealing all 8 sides

together, I should have made it with tapered panels to give it a smooth

transition from the roof angle up to the tip; starting at the bottom

with the same 8/12 pitch as the roof. It would look better and

made the attachment more stable. I also now use stainless steel screws

instead of nails so it can be removed without damage for reroofing and

then reinstalled. I also integrate a hidden roof vent with a lot of

the roof caps we make these days.

|