|

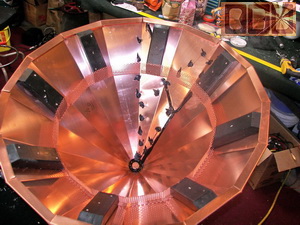

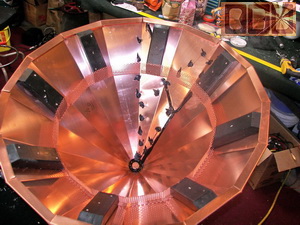

This is a 16 sided turret roof cap made

for our clients; Dobbins Construction, Inc. in Laurie, Missouri

for their client's circular turret roof peak.

Their phone # is: (573) 374-7856.

This shows the main base cap formed to be 35.5"

wide at a 12/12 pitch angle.

I was able to make

14 sides in a single piece, then splice on the last 2 sides behind where

it would not be seen in order to make it as seamless as possible.

|

|

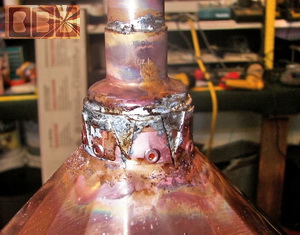

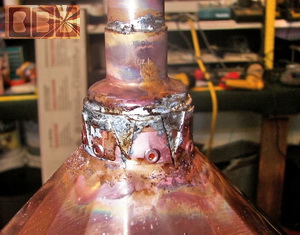

This shows the preparation of the finial support

pipe to connect with the peak of the main base cap. This is a 2" to

3/4" copper pipe reducer with a cap soldered underneath to seal this

pipe and allow for an attachment with long copper rivets that will not

get in the way of the brass rod that will sit inside this pipe.

|

|

Here is the way we attach and seal the bottom

of the finial support pipe to the tip of the main base roof cap. After

carefully checking the level I clamp it to the flanges of the roof cap

center and solder it in place. Then I drill the holes for these

extra long copper rivets to go through the 3 to 4 layers of copper.

|

|

This shows the cap base with the finial support

pipe attached. The right photos shows the underside of this

|

|

These are

caulked again from underneath over the seams and rivets to make certain

they will never leak. I then covered the caulk with a special tape to

shield it from oxygen to increase it's life span..

Then I do this over the top side that will not

be seen once complete. This is a special caulk that cost about

4 times as much as the caulks you would find at the local hardware store.

|

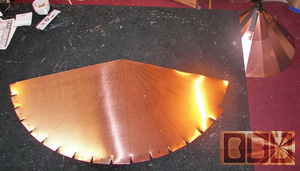

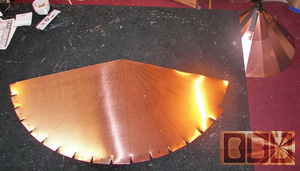

This is the steeple

cone drawn out on a sheet of copper to have

2 of the sides overlap. The second

photo shows this cut out just before bending

it into shape. The cuts along the

bottom are for flanges to be bent underneath

for riveting through to mount this steeple

cone, so the rivets are not seen.

|

|

I weighed it without

the blocks and screens. It was 24.5#, so that equates to 19.6 sq' of

copper used to make it X $45 = $882.50. Here is the finished roof cap

with the small antiqued copper Bass style weathervane they ordered with

it.

|

|

Even though these are fairly light weight, I take

crating very seriously. It is tricky to make a light weight crate that

is also very sturdy and strong to shield the copper roof cap during

shipping. The trucking company will most likely stack other boxes and

containers onto of this crate to fill the truck as full as possible.

So far none of these large crates have been damaged.

Cost: $882 for the roof cap copper

$125

for the finial support pipe

$65 for the roof vent blocks & screen

$246.50 for the Bass style finial and brass rod

$1,318.50 total w/weathervane,

crate, & shipping

|