|

The John &

Jennifer Boll Turret Cap Photos and Description Page Updated 9-20-2004 |

|

|

Company Profile |

|

Roof Caps |

|

Chimney Caps |

|

Scuppers |

|

Gutters |

|

Shipping | Contact Info |

|

The John &

Jennifer Boll Turret Cap Photos and Description Page Updated 9-20-2004 |

|

|

Company Profile |

|

Roof Caps |

|

Chimney Caps |

|

Scuppers |

|

Gutters |

|

Shipping | Contact Info |

.

|

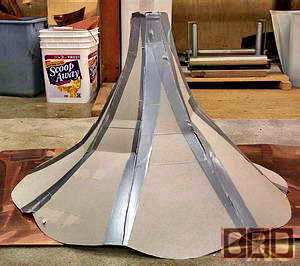

Fabrication of a 30" wide, 12/12 to 32/12

pitch, octagonal copper turret cap, with weather vane support pipe |

|

Homeowners John and Jennifer Boll in Jellico, Tennessee contacted us on Saturday March 27, 2004 in regards to re-fabricating the steel roof cap for this turret on their charming classic house. The steel cap they had was so rusty, it had literally fallen apart. They did not know how to calculate the roof pitch, since it varied in pitch all the way up. The owner followed our instructions on this web site and made a cardboard model out of cereal boxes taped together with duct tape from the old cap (as you see below). They mailed the cardboard model to us, so we had a template to work from. |

The original turret roof cap was designed to have a sloping curve to a peak and had an ornamentation at the top. We asked if they wanted it to have this same sort of design, and discussed the cost differences. They opted for a more simple fabrication, with only one seam, instead of 8 seams to seal. |

|

Below shows the roof the new

cap will go on with the new roofing installed.

Hence the walkboards you see there over the roofing. |

| Here is the bottom two sections we made for this turret roof cap. We made them in these different sections to alter the angle of the cap to gradually spiral to a peak. |

| The upper lip of the lower-section has been

bent outward and down to drill the rivets into. Without having

to rivet through the inside of the cap, so there is nothing to seal

with caulk. Here it the cap with the mid-section set on the lower section cap for fitting (as shown). The tip in the upper section is cut open for the copper pipe used to support the weather vane mast. |

| This is a center mast support to go inside the mid-section. The tabs are bent at a 90 degree angle upwards to allow the wood block to fit in. We then bent the tabs inwards by hand. Even though it should not be getting wet, we sealed the wood on all surfaces. |

|

The holes in the copper plate are to screw up into

the wood block, as you see here. The holes drilled in the tabs

(shown above) are to rivet this into the

mid-section cap. |

| Here is the cap with the bottom brace riveted in, and the copper pipe going up through the center. We then solder the copper pipe to the center tabs. |

|

This stainless steel pipe clamp was then added over the tabs to insure it would hold steady. We then covered it with the same caulk that we use to seal gutters. We sent the clients these digital photos each night to get their feedback of what they thought of the progress, and allow them to address any ideas or concerns. |

| Below left is the mid-section

copper cap showing the base support for the mast fastened in place.

While below right is the mid-section riveted onto the lower-section cap. We ran a bead of caulk where they meet and covered the caulk with cloth gaffer's tape. This is more to seal out insects and to resist any movements, more than to seal the rain water out |

| Here is the side view with

all 3 sections together and sealed It took about 10 square feet of copper sheet metal to make all this, not including the cut off waste. Fabrication price was only: $250 plus the $100 for the sealed weather vane support. That included all of the wood crate and shipping costs. |

|

This shows the comparison of the finished cap and the model of the old turret cap the client made. |

| Below is an example of the

letter of instructions we send after shipping

off the order: At 08:14 AM 5/19/2004, you wrote: Hey John, Detailed Installation Instructions: Yes, we got it yesterday. Thanks. If you don't mind, we would love to see

pictures of it installed. Even in steps as you install it, as long as

it does not compromise your safety of course. If you do not want them

used on the web site for any reason, just say so, and we will honor

your desire. Thanks. It was good working with you. Below are more pics of its development. Enjoy: |

|

Here is the final product of our hard work, and the installation by the owner. We try to work a good balance of strong, changeable, and easy to install with clear instructions as shown above. |

.

| Click this

photo to go back to the Custom Copper Roof Cap main page. |

.

|

Click here to go back to the Custom Copper Roof Cap main page to see more of the different caps we have created over the years. |

|

Below is a

photo of our |

|

We were also a 1997 finalist for this same award. See our referral web page to see how we managed to be honored with this special award |

Homepage |

|

|

Company Profile |

|

Roof Caps |

|

Chimney Caps |

|

Scuppers |

|

Gutters |

|

Shipping | Contact Info |

.

.

.

.

.

.

.

.

.

.