|

CBD's

Lead

Time

|

|

You can see what our work schedule is by going

to our

Latest News page to find out our most

current lead time. We strive to check our e-mail at least a couple

times each day even on the weekends to respond within 24 hours. Give

us a ring if you have not received a personal response within a business day

to see if we got your message.

This process should go swiftly,

depending on how fast you are able to answer our questions. We

do have a toll free phone# listed on our

Contact

web page, but I may be busy in the shop or up on a ladder

when people seem to call. Not just sitting at my computer. That process

can take several hours to do the careful calculations

(as long as I have the info I need).

I also do not like to quote costs for work over the phone because then

neither of us would have a written record of what was said.

With this comprehensive internet exposure

we've become pretty busy. After we have locked down all the details and received

your deposit we are still booked out several months with projects before

we could begin the actual fabrication of your project, so be prepare

to hear we will not be able to deliver your custom project in short

order. We currently have no teams of workers to speed up production. We demand

excellent craftsmanship and have not found others to equal our meticulous

expectations and creativity. So it is simply on a first come-first

serve basis hinging on the receipt of the deposit.

If you are confident we will be able to workout a

reasonable contract you could send an approximate 1/3 deposit to lock your project

in our cue as soon as possible while we work out the details, taking

some of the pressure off to make hasty decisions. That deposit would be

90% refundable if we

were not able to work out an agreement to your liking. We want serious inquiries only, since that would push our schedule

out that much further, causing us to loose other prospective

clients, so that 10% reservation fee is not refundable.

|

|

General Cost & Prices

|

The cost can vary

widely to fit

your needs for a custom fabricated item due to the size, complexity, and

features. Our

chimney cap projects over the last 2 decades have run between $200

to $600 ln' of the chimney top measurements. Our most popular

Tuscany arch style now averages $400 ln'. This gap largely depends

on the thickness of copper used, height, style, ornamentation, an

internal pan (if needed), and the need for a custom sturdy shipping

crate with truck freight. Since most of our clients do not happen to

be local to the Porland Oregon area where we reside. CBD is not a

francise with multiple locations. Without the singular passion of

David Rich at the helm CBD would not exist.

Another way to

calculate the cost is around $30# base rate to $60# for more ornate

work calculated from the actual weight of

the finished project plus the cost of a crate and truck freight if needed. Our pricing is not calculated

along with the the

scrap cut-off included. This way our Client are able to double check our

cost with the actual weight once it had arrived; to see how honest CBD was, so there is no deception

possible. This has been part of my ethical business practice for

the last 3 decades, yet unheard of with any other metal shop across

the country. If your project does come in under weight your final cost will be

discounted accordingly. Although, many projects have come in over the estimated weight

due to the extras CBD tend to put into each project. Although, a

written quote places a ceiling

on the cost on that project. Unless there are substantial authorized changes made after the quote

was accepted it would not cost more than quoted amount, but shipping

cost could fluctuate a bit. You are also welcome to arrange your own

freight, since we do not mark up any freight cost. Often it winds up being a better bargain in the end,

given the free copper you may get.

Besides our very

unusual business practice of discounting work like this, we have been

told our quotes are quite reasonable and even cheaper than many other

shops. CBD also gives discounts to clients who aid in the quote

process by carefully reading over these web pages and clearly convey

their needs in their first e-mail with good clear photos; in order

to minimize the number of e-mails needed to iron out those details.

If you have read this far, you are off to a very good start. Feel

free to mention this discount in your e-mail.

Our base rate for a more basic custom project

(not including crate & freight)

is $35#.

Base Rates per square foot charges come to:

$43.75 sq' - 20oz copper for 1.5X strength compared to

standard 16oz

copper (is most commonly used)

$52.50 sq' - 24oz copper

for 2X strength (CBD's minimum standard)

$70 sq' - 32oz copper

for 4X strength

$105 sq' - 48oz

copper for 12X strength, or hammer dent resistant

$15 sq' - 1 X 6 ipe

hardwood used in the base/skirt angle cut on all 4 edges

$18 sq' - 5/4 X 6 ipe hardwood used in the base/skirt

$22 sq' - 16 gauge stainless steel spark arrest screen

$25 sq' - 13 gauge stainless steel spark arrest screen

Of course, tricky ornamentation and curves add substantially

to the complexity and cost of a project.

If you are not local CBD will need to add

the cost of a sturdy custom wood crate with packing along with the cost of truck

freight w/hydraulic lift-gate

residential service in most cases.

We have no control of the shipping time,

other than to charge you a huge cost for 2 day, or overnight shipping,

which can cost more than the custom copper fabrication. Most of

the ground shipments have not been taking more than a week for delivery

from the West Coast to the East Coast,

so it hardly seems worth the cost of moving such large projects just

a few days sooner. We have rarely had had a client who was willing to

pay that much for Express Shipping.

Payments

To get your project set within my workload, here is the

payment schedule:

$600 and under a

full payment up front is required for those small projects.

Over $600 only a 1/2 down deposit

is required for these medium size projects, with final payment before

it ships.

$2.5k projects and above just a 1/3 down deposit is required for

those larger

projects. The second third when we show you we have begun work

on your project through digital photos. Then final adjusted payment before it

ships.

$20k and above we only

require a 1/4 down payment at the time of scheduling, 1/4 when

begun, 1/4 due at half completion, and the final adjusted payment

once complete, before it ships.

By then you will have seen

numerous photos of your project and have much more confidence that

you will be receiving just what you ordered, and I would have a chance to weigh it in order to recalculate the final

cost down to what copper actually stayed in your project. A detail

that you could double check to see how honest I was.

Trust

We all know what a scary ugly world it

is; full of liars and cheats. I believe that our referrals web page,

thousands of step-by-step photos,

and

Business Integrity Award

from the Better Business Bureau should help give even the worst skeptic confidence

in my ethical responsibility and devotion to my clients. Because

of this we have only had less than 5% of our potential clients express

discomfort with our payment policy. This has not been much of

an issue, but if you do not trust CBD, you should simply not do business

with CBD under any terms.

|

|

What Sort of

Information Will We Need?

|

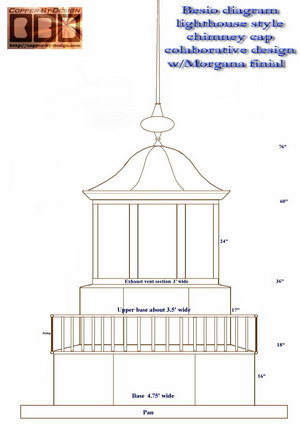

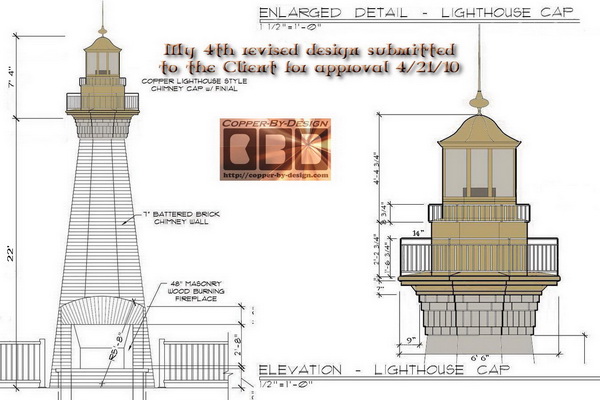

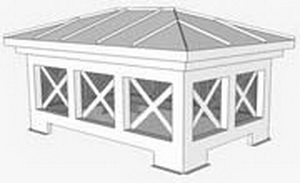

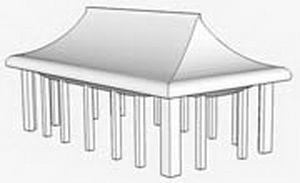

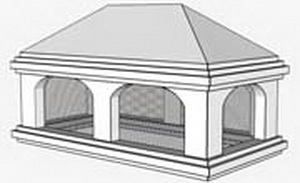

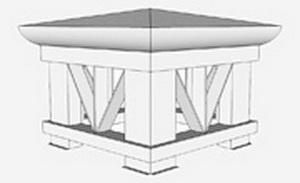

| I understand how hard it is to decide on a

style of chimney cap that would look best for your house and getting

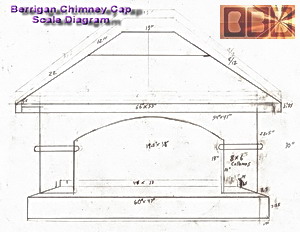

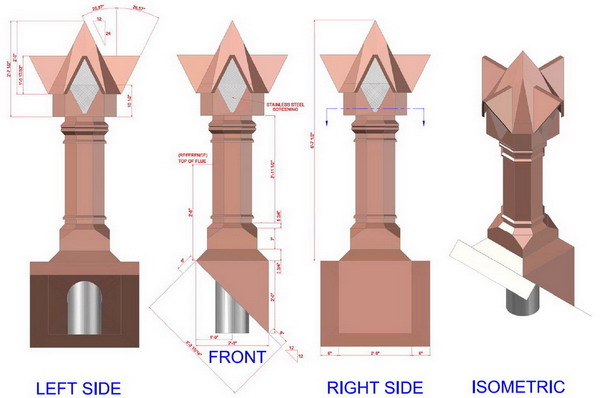

the measurements we'll be needing. Here is an example of what

a client sent to us that they had done to help them decide what style

to go with, but this not not required. We post as many photos of the

installed chimney caps we can, but often time we never hear back for

our clients after shipping out their order.

To fabricate a copper chimney cap for you,

we'll need to know a few details:

Your Contact Info:

Your complete contact info to send the

copper chimney cap out to you: name,

address, & ph# where you can be

reached in case they have trouble delivering it. Shippers prefer a business address

to deliver it to, so there is a better chance to have a person there

to receive it, but that is not a requirement in most cases. We will

need to know if you will need a lift-gate service at the job site to unload

the crate.

Style:

What style cap you are looking to have us build. If you do not find

what you are looking for in the examples shown on our

Chimney Cap page you can have your

ideas diagramed, then scan it or take a photo of it to send us as a image file,

or send up any other images you find that could show me what you

have envisioned. We

have a cable modem, so large file sizes are not a problem. Everything

you can do to help convey your wishes will aid in getting just what

you want from us, and we will better be able to quote you a firm price. Our

primary goal is to provide you with your dream cap at a price you can

live with.

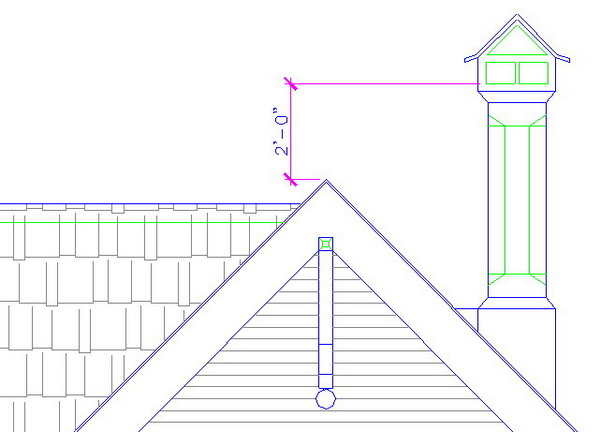

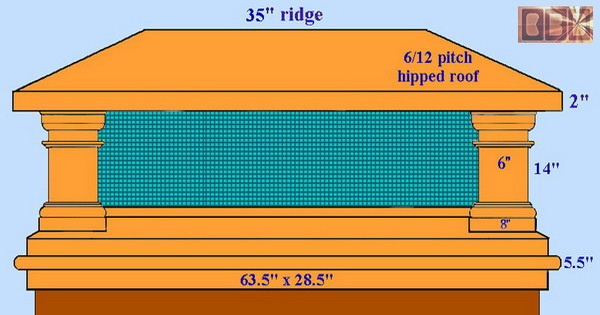

Roof Top Angle:

The angle of the roof that would

be best. I do not make flat top chimney caps. It is best

to match the roof pitch of the house roof to help make it look like

it fits with the style of the house. Normally this is calculated in the inch rise per

12 inches straight out level. Example: a 6/12 pitch is half

of a 45 degree angle. The second number is always 12.

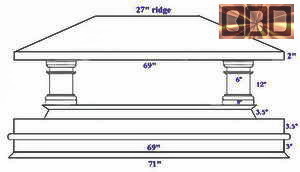

Sizing:

Before I begin fabrication I will

need to know how long and wide the base needs

it be to fit over your chimney to secure properly in high wind situations,

which can also be removed for cleaning. We also need to know how wide

you want the roof in relation to the base. If I make this exactly to your measurements, but it does not fit right for some reason you would be very unhappy with your order, so my goal is that it will install without a hitch. If you following these instructions this should prove to give us this result. Have them use a pair of straight 2X6 boards that are

longer than the longest sides to lay horizontally against the sides of your chimneys

near the top where the base will be positioned to measure the span on each end

between those boards. Then repeat this for the opposing sides of the

chimney, so you'll have 4 different measurement charted looking down

over the chimney with the front side of your house listed. This will

give us the best possible measurements taking account to any irregularities there may be. I will

then add 1/4" to those measurements you provide to allow for a little slack, so it is not too tight. What I will need from you is just those tight measurements of the sides it will go over.

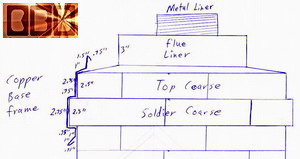

Obstructions:

What size and type of flues are protruding out

of the chimney top. What is the inside displacement, so we can match

the exhaust flow with the side vent spark arrest screening area on each of the 4

sides, so there is no flow restrictions. Digital photos may be needed

looking down over the top, so

we can better see what the chimney cap will be mounted over to be sure

it will fit properly and not give your installers any grief.

|

|

Why do we primarily

use copper?

|

| We prefer

to work in copper for the client's advantages, not ours. Here is a few

of the reasons why: (a)

Copper can

handle heat much better than aluminum (as

long as it is not soldered together).

(b)

Copper costs

the same as stainless steel, but has several advantages, as listed below:

(c)

Copper

sheet metal is thicker than standard

stainless steel sheet metal for the same

strength, so it is heavier for better stability in high winds.

(d)

Copper does

not need to be painted, resolving any future repainting issue.

It is a metal that is meant to be seen with it's attractive patina effect

that darkens the metal within a few months exposure to the elements.

It remains a classy look, and less conspicuous than stainless steel,

which remains a bright shiny eyesore, and is prone to mildew on the

Northern side.

(e) Copper

will not mildew and has been known to aid in reducing mildew and moss

growth below the area it is installed.

We feel that since the cost labor is by

far the largest part of the cost for any custom work like this, why

use cheaper materials? If it is built well, it is common knowledge that

copper has proven to last out in harsh elements for well over a century.

But this is the key we place most of our focus on "If built well". Even

if it were to be made with a steel that is 3 times as thick, it would

still only last 1/3 as long as copper. That is a 9 to one ratio or better

over the most common metal used for chimney caps, but when you calculate

the lost labor of fabrication and the replacement installation cost,

the spread is far greater.

Even if you got a fantastic deal on a smaller

chimney cap made of steel for only $600, in the long run that is actually

more expensive than paying over $4,000 for a larger more decorative

copper unit that would last well over a century. If you want to avoid

the rust stains it will cause if left up there too long, you would have

to change out the steel unit every 10 years or so, and pay to cover

up those ugly rust stains.

Then there is the resale value of the house to consider, which is likely

greater than the cost difference of using a cheaper metal. That issue

alone would be profitable to go with a better unit.

|

|

How

thick is the copper we use?

|

For some reason they do not use the

same scale for the different types of sheet metal. Copper is gauged

by weight per square foot, so if they use a different gauge it is likely

that they are not using solid copper. Some shops actually use a

micro thin copper coated stainless steel or just cheap steel sheet

metal painted to look like copper, which will rust and fall apart in short order. Most fabrication shops

that

are willing to with copper tend to only use a very thin 12oz or 16oz copper sheet

metal to help bring down the high cost of production,

since it is easier to cut, drill, and bend. Although, keep in mind

how most of what you are paying for is labor and freight. That thin

16oz copper has been the standard in

the industry for many decades. It may look swell, but is quite

fragile. CBD uses a minimum of 24oz copper these days, which is at

least twice as strudy. For some reason they do not use the

same scale for the different types of sheet metal. Copper is gauged

by weight per square foot, so if they use a different gauge it is likely

that they are not using solid copper. Some shops actually use a

micro thin copper coated stainless steel or just cheap steel sheet

metal painted to look like copper, which will rust and fall apart in short order. Most fabrication shops

that

are willing to with copper tend to only use a very thin 12oz or 16oz copper sheet

metal to help bring down the high cost of production,

since it is easier to cut, drill, and bend. Although, keep in mind

how most of what you are paying for is labor and freight. That thin

16oz copper has been the standard in

the industry for many decades. It may look swell, but is quite

fragile. CBD uses a minimum of 24oz copper these days, which is at

least twice as strudy.

They also will not have bracing inside these thin roof covers.

This detail would add about twice the metal needed, but makes a huge

difference in the strength of the unit to resist the elements they will

be exposed to. Like heavy snow loads, high winds, and being hit by a

falling branch.All of our custom

work in the last 18 years has been fabricated with a thicker

20oz solid copper sheet metal or even thicker

where needed. All the way up to 48oz copper. Then in 2017 CBD

had

upgraded our standards to 24oz copper for most chimney cap work. To give you an example

of this statement; 20oz copper is so rarely requested by contractors

and other shops that I did not even know our metal supplier could order

20oz copper sheets until 2003. A full decade after specializing in sheet

metal work. So, from 2003 to 2017 all I order is 20oz copper in large sheet form for

these custom fabrication. Now CBD uses more 24oz

copper than 20oz copper.

We have an old copper scupper on display

here that I had replaced it back in 2002, which is a classic design

you will not see made in these modern days. It had a few holes worn

through the left side because they used such a thin copper in it's construction.

Also the soldered seams were cracking apart even though there was no

sign of an impact. The client had already bought a new scupper from

a different shop for me to replace this with. It was not nearly as ornate.

I could see how the new scupper was no better built, so I made a funneling

copper liner for it to be hidden inside, so this same failure would

not happen again. At least it would last twice as long this way.

|

|

Patinas and Other Finishes?

|

We have rarely been contracted to pre-tarnish the new copper surface

to make it look aged before you receive the products we build, since

the copper will naturally turn brown within a few months of exposure

and the heat from your fires will also turn the copper different

colors.

There are

numerous different mild acid wash soaks that can be applied and then

a lacquer applied over it to retain that look, but the lacquer

finish will not handle the normal heat generated, so that would be a

waste. Here is a link to a company that specializes in these sort of

copper patinas. I have their sample physical pack of the different

colors and striations:

http://www.colorcopper.com/

Here's a

link to a web

site that shows some of the different chemical compositions to get

different colors out of the copper surface:

http://www.sciencecompany.com/-W160.aspx

What about Retaining that New Penny

Copper Look?

Personally I agree they look nice with that new penny copper look,

but most clients seem to like the tarnished look better, and it's

near impossible to do this with chimney caps because of the heat. You could lacquer

it, but even if it were a high temp coating a decade later it will start to peal off and look

terrible; tarnishing between the cracks and require some expensive

restoration. The raw copper will also help retard growth of moss and

mildew on the chimney surface below. If you were to polish and wax

it there would be no unpleasant side effects, but it would not last

very long.

The only good way to get a lasting new look would

be to have it layered with rose gold leaf, or PVD coated like the

better door knobs, which is just a colored chrome plating to look

like copper, but it would probably cost more than the amount you pay to have this made and delivered,

so it would be impractical. |

|

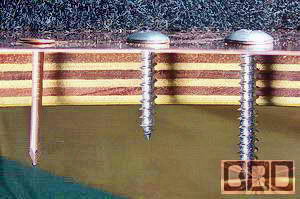

Fasteners

|

At CBD we provide the #14 shaft stainless steel mechanical fasteners

with each project to make sure it will be secured well and still be

removable decades later without damaging the unit. We do our best to

design chimney caps that will be attached strong enough to withstand

the highest wind gusts you are likely encounter in your area, yet still

be removable for flue cleaning, or some other servicing that may be

required over the next century or so.

We have had some

clients ask about a hinged chimney cap. It could be done, but the

strength would be compromised. If the Chimney Sweep did not latch it

just right when they're finished it could blow open and cause some

damage. You also run the risk of them denting or damaging the

chimney cap in the course of their work. So it has proven best to

just remove the whole chimney cap as a one piece unit, set it aside

where it is safe, and reinstall when their done. The way we build

the bases they are much less likely to fly off even if they forget

to tighten the screws again

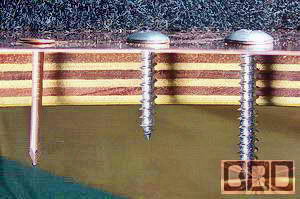

Nails:

We do not recommend using nails for mounting any of our products

other than copper roof shingles. There is a very good chance it will need to be removed

again for servicing and the flues may need swept out. On the left is

a solid copper 1.5" nail we supply for chimney flashing kits.

We also have 2" copper nails and hardened masonry nails if

requested. These would be the most inconspicuous looking fasteners,

but these are not much good for chimney cap attachment.

Standard SS (stainless steel) Screws:

in the middle is a common #2 Phillips head w/#10 shaft SS screw just 1" long with a low profile

truss head. I feel this screw is too small and fragile.

We stopped using the #2 slotted screws over 15 years ago, even for aluminum

downspout attachment with our gutter systems replacements.

Larger SS Screws:

on the right is a #12 shaft SS screw we use for gutter installation.

Although, we provide #14 shaft stainless steel screw with our custom

chimney cap fabrications, which is 1/4" OSD. We do this so we know the installers will use good

sturdy fasteners. We have these in a 1.5", and 2.5".

These takes a larger #3 Phillips screwdriver

tip, which is a lot less likely to strip out during installation.

Besides installation this means it is a lot more likely to be

reusable when your chimney cap needs any sort of servicing latter on.

We have hex head SS lag screws as well, but they would have a much

larger noticeable head showing. I highly recommend using an impact

driver to reduce the wear to the head slot of these screws. Or any

work with screws you happen to be doing.

SS Bolts w/Locking Nuts:

we also supply the client with stainless steel bolts and locking nuts

where needed, or use them for assembly where rivets will not be enough

to hold the structure together.

Instead of just a brick chimney lots of

modern houses are built with fireplaces that use an insolated flue pipe

that is covered up by a wood chase built w/stud and plywood. The outside is

sided and painted.

Fancier houses will have a stucco or rock facing mortared over the wood.

For these types of chimney caps we usually build a custom angle cut

wood base for the chimney cap to rest on

(shown above painted blue mounted over the crate

base w/screws) This frame bolts down to

the studs and overhangs the exterior cover. If the chimney box has a

double top stud plate (as shown here),

they are just be nailed down, which could be pulled off in high

winds, so for these wood frames we provide several 8" long lag

screws with washers to fasten this base deep into the studs below to secure it properly.

|

|

Minimum orders

|

| Our minimum order charge

for any custom work is $300, but since most copper chimney caps we make

cost well above that, this has not been much of an issue. |

|

What about Volume

Discounts

|

|

Yes, we

will discount large orders of the same design. We also give discounts to clients

who aid us in the quote process by carefully reading over these web

pages and clearly convey their needs to us in their first letter with

good clear photos, in order to minimize the number of e-mails needed

to iron out these details. If you have read this far, you are

off to a very good start. Feel free to mention this discount in

your e-mail.

|

|

As for Propper

Instalation:

|

I suppose theoretically a few guys could

try to muscle one of our chimney cap creation up a ladder and

traverse your steep roof, but there are several critical flaws with

that plan. Especially with a large chimney cap. Namely; the fact

that they do not make a ladder rated to handle that much weight for

a chimney cap along with even one man. This alone should be a

deal-breaker for anyone to ponder this type of installation. They

also greatly risk damaging your roof and the chimney cap if

something goes sideways, and they would not be able to afford to

replair your roof or replace that chimney cap they thrashed.

In my vast

experience I would highly advize using a crane over the use of my 2'

wide 20' long aluminum platform that is rated for 500#. We have used

it to slide up a smaller chimney cap that this sitting on a custom

wood sled we had made. We had to pull it up with a rope to a one

story flat roof, which was very difficult, and even harder to raise

it up over the chimney while on that flat roof. There is also a very

small chance an installer happen to have a nice wide platform like

this, since most platforms are only 14" wide. Here is a link to see

an example of this:

https://www.facebook.com/1DavidRich/photos/a.1373373982684768/1394629167225916/?type=3&theater

I had also used a 32' long ladder for this

sort of un-manned slide, but it was very steep, wabbly, and quite

difficult. Here is a few photos of that as well:

https://www.facebook.com/1DavidRich/photos/a.2016431418379018/2023279054360921/?type=3&theater

Here is a good example of how to do this

propperly, which took less time to install all 3 chimney caps than

it took the driver to set up his rig:

https://www.facebook.com/1DavidRich/photos/a.1333178243371009/1348596531829180/?type=3&theater

In my

experience NO other option should be considered. I would not even

recommend using any sort of man-lift for several reasons. Most

impotantly is their lack of experience opperating it, compared to a

seasoned crane operator. Huge difference! People have died from

these falling over. I would not even trust myself at the controls.

That's why I hire the professtional crane operators.

To open the crate

and safely remove your new chimney cap you will need a #25 Torx tip

in a drill/driver handy for the wood crate. It would be best to have

someone there to quickly open on side of the crate to inspect before

the driver leaves to make sure it is in good order. Especially if

you see any damage to the outside of the crate. You only need to

remove the #Torx screws on the upper sides to remove the top and

lift off the top once it is free. Then any one of the sides can be

removed at the sides and bottom screws. It would be best to leave

the chimney cap on the crate base until you are ready to do the

lift.

You'll also need the #3 Phillips tip

(included) for the stainless screws to fasten it to the chimney. It

is recommended to wear clean gloves when handling the copper. It

will help from getting finger print oils on the copper, which will

tarnish sooner than the rest of it's surface leaving it spotty. It

will also help you from the possibility of getting cut from the

edges of the copper, even though we went to great lengths to hide

all the sharp edges. We wiped it down before it left us, but it may

have still darkened a bit in transit, so you may want to give it one

final polish before installing it, so it is sure to tarnish evenly,

but it will also develop irregular heat marks the first time you use

it, and change a bit with each use. The SS screen will darken as

creosote coats it after numerous uses.

Condense and

dispose of the crate as you see fit, or use it to make a cute play

house for children by cutting a door and windows, sanding off the

edges, and painting it. The sides can be reversed to make it more

attractive on the outside.

There are screws in the corners and on the

cross boards. It's glued together, but it should crack apart without

too much trouble.

We strongly advise

that you use a cordless impact driver to set these SS screws, which

is far better than a standard drill to help avoid damaging the

Phillips slot. Trust me on this one. If you have not yet bought an

impact driver, do so. It will be one of your best investments for

setting any screws. Makita makes a nice light weight 18V cordless

driver with the good Lithium batteries and a brushless motor model

LXDT01.

As to the installation; with the right

equipment this should be fairly easy and quick to do. Using the

provided lift kit you will want to lift up on the upper eaves so

there is nothing underneath to be in the way of setting it down over

the chimney, like your fingers. Once it is settled down in place the

SS screws just need to be run in enough to apply a little pressure

against the stone work under the edge of the slab, but be careful

not to over tighten and crack the stones. If they are not long

enough we also provided you with longer screws to swap out if

needed.

At the time of installation feel free to

call me with any questions to reach me a lot faster than through

e-mail. Please let me know how it turns out, and we would love to

see any photos you are willing to share. A written report also help

me learn how best to advise clients in the future, so don't be shy

to say it like it is. |

|

Are CBD Fabrications UL

Listing Certified or Compliant?

|

The short answer is

'yes' and 'no'. You should be able to clearly see how these are designed and built far better than UL Listed products. Without even being an

Engineer; you should be able to understand how our unique designs far exceed

UL Listing requirements. It would be far too time consuming and

expensive for CBD unique designs to have each chimney cap creation tested and

certified through Underwriters Laboratories. Beside the cost to

build you a second chimney cap once it has past inspection, I would

have to make one before that for them to beat up and pay a $10k fee

for this. So, they will not

certified UL Listed products.

If CBD were to down-grade our build

standards to

just the bare minimum UL Listed requirements it would go against my

ethical standards. It would only be feasible if I were going to make thousands of a

single design in that one size. Then this would be more practical and something I would

have done, but I have rarely been able to use a template twice, as

these designs are each so different from one another. It would be

completely impractical to go through that process of making 2

identical chimney caps each time and

pay for the testing process. It woul greatly hinder my progress with long delays. UL listed products may be a good

idea, but are not the law that we have to use only UL listed products.

That would still not guarantee you will have no problems with it, any

more than I could make such a promise.

The key factors to

consider in a chimney cap design:

(a) Is this design providing enough screened surface

area to not cause an exhaust restriction given how this will be

used? ie: type of fuel being burned and flue size. The design should

allow for at least 1.5X that of the inside measure of the flue(s)

for each of the 4 sides; as the direction of the wind will change.

That is

a total of 6X the flue size in all.

(b) Is this

going to handle keeping most of the wind-driven rain out effectively. Even form splattering?

(c) Is this design constructed well to be

sturdy and attached sufficiently well?

(d) Can this be removed

reasonably well for serviced as

needed?

(e) Can it handle the heat it may be

subjected to? Keep in mind solder melts at just 450 degrees, or just oven

temperature. At a 1,200 degree melting point aluminum is not suitable

for a wood burning chimney cap. Copper is rated to handle up

to 2,000 degrees. Even higher than steel. |

We

have only seen one other manufacturer on the web who makes similar copper

sheet metal chimney pots, which are sold by several different retailers.

They are named after chess pieces, but I think they look more like light

houses. I have not heard or seen where they take orders to build custom

work like we do for specific sizing or style. They are also more expensive

than our work; considering the fact it is a thinner copper and are rather

plain looking.

We

have only seen one other manufacturer on the web who makes similar copper

sheet metal chimney pots, which are sold by several different retailers.

They are named after chess pieces, but I think they look more like light

houses. I have not heard or seen where they take orders to build custom

work like we do for specific sizing or style. They are also more expensive

than our work; considering the fact it is a thinner copper and are rather

plain looking.