|

We had a Builder,

of MasterPlan Construction - 631-428-7576 from the

Hamptons in New York contact us about building a large copper leader-box for the

development they are building. Here is the first diagram he sent to us to

give us an idea of what they wanted.

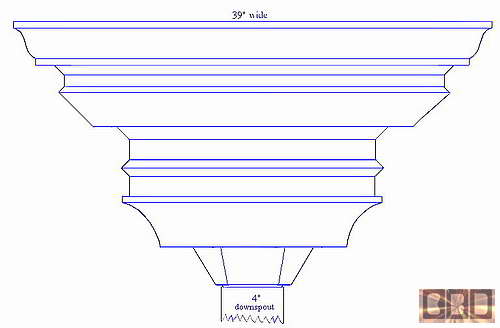

Below

is the scupper design We drew up for the clients to consider. It is similar to

diagram #2, but a lot wider, making it much deeper and taller as well. We made it with 20oz copper, with the top section

being made from a section of K-5

gutter that had the bottom and back side bent down into the shape of this scupper

diagram, so the top half was one piece without horizontal seams

|

This

shows the section of that K-5 gutter with the bottom bent down and the cut

lines drawn on the protective clear plastic film covering the copper surface.

|

It is

sealed in a clear protective plastic

sheet that is to be peal off when it is installed. Here is the first

corner upside down being formed.

|

| This shows the

inside of that corner after it is riveted together.

|

Here is an angle view of the 3 sides

riveted together with the first mid-section in place.

|

|

Here is the other 2 midsections in place

and riveted together.

|

This is the inside of this, still upside down, showing the

tabs that we will fasten the back to.

|

|

Here is it is laying down on it's back.

|

Here is the beginnings of the bottom

section.

|

|

Here is the main front sections of the

scupper finished from behind with the back laying down flat, ready to be

attached.

|

Here is This shows the back side

attached. It has 52 rivets, but latter gets another 14 rivets to secure

the back to the side walls.

|

|

Here is the scupper propped up to lean

back a little to balance, since it it still a bit front heavy.

|

Here is an angle shot from below.

|

|

Here is a shot of the inside. We use a

clear caulk, but then spray a brown over it to use as a solvent to

finish pressing the caulk into the seams and over each rivet inside. It

also helps to keep the sun lithe off the caulk for better life of the

caulk.

|

Here is an angle view of the inside of

the leader head we made.

|

|

Here is the outlet to be mounted in the bottom of the

leader head.

|

Here is the leader head upside down with

2 holes drilled in the bottom to cut out the section needed for the

outlet to be mounted.

|

|

Here is the bottom of the leader head cut open for the

outlet to be mounted.

|

Here is the outlet to be mounted in the

bottom of the leader head.

|

|

|

This is the outlet from the inside of

the leader head.

And the back of the leader box with the outlet mounted. |

|

Here is looking down inside the leader

box with the 3/4" copper pipe mounted across the top of the back for

support. It has the 2" stainless steel mounting screws run through

that pipe.

|

Here is the leader box mounted on the

wood frame of the crate we are making here.

|

|

This is the leader box from different angles.

|

|

|

This shows the copper pipe along the back from a different

angle.

|

The crate frame is screwed together. We added another pair

of boards over the leader box. Then stapled cardboard over this frame

for shipping.

|