|

Experience?

Our main specialty has been to design and

fabricate exterior rain management products, but we have been asked to do some

of this type of interior work as well.

This refined interior work is not something

I tend to push, as it will be expected to be nearly perfect at close inspection,

which is very difficult, as with anything

custom hand-made, such as this. Clients are used to seeing most store bought

products that were mass-produced and expect a

flawless appearance and finish, or it may be returned to the store. I cannot

afford to simply remake a slightly defective copper clad countertop.

Finish

Quality? Finish

Quality?

To be frank, these kind of projects may have minor

scratches and dents, because we do not have access to perfectly polished

copper sheets to use for projects like this, so I cannot guarantee your satisfaction with the new copper finish

that you may expect. You

are then welcome to have it polished as much as you want by those who

specialize in metal polishing work. After it has developed a patina you may

not notice those minor imperfections. Some clients love the rustic

hammered copper look, which would help to hide any future dents or scratches

that may occur.

Advantage of

Copper?

Beside the unique look of copper, the

main

preferred advantage

of copper over stone or stainless steel is largely for it's anti-microbial properties.

Very little cleaning is needed, since the main advantage of raw copper over

any other countertop surface material is how copper is

much more

anti-microbial, which naturally kills germs on contact. As explained from

this link below. Stainless steel may look cleaner than tarnished copper, but

looks can be deceiving. That stuff that can kill you are not seen with the

naked eye.

My understanding is how some

hospitals outside the USA have impliments more copper shelving and such to cut the staff infection rate quite a

bit.

It also has a character you cannot find with any other type of surface;

with it's ever changing appearance as it develops it's patina over time, which does not stain or

rubs off on other things.

Strength?

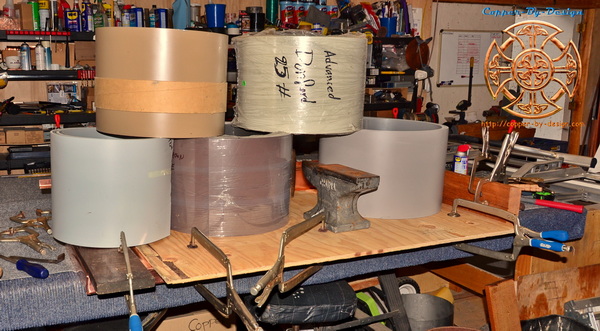

Most of these

projects are made with a thick 32oz copper, which is about 4 times as sturdy

as the more common 16oz copper used by most sheet metal shop to save on

their material cost. That is if they are willing to work with copper at all.

This 32oz copper sheet stock is not

found at most other sheet metal shops at any price. This is

just twice as thick as the 16oz copper, but much stronger to

help be scratch and dent resistant for many years of service. Why use a

life-time metal like copper if it's just thin and frail?

Heat Issues:

Copper can

handle upwards of 2,000degrees. Even more than steel. A great deal more heat than the wood base

and contact cement. Be advised that the heat from

a pot of food set directly on the counter top

could expand the copper momentarily and pop the glue loose, so using trivets should solve

this issue.

Feel?

The

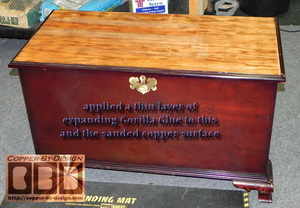

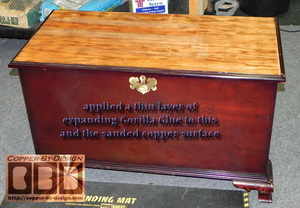

copper sheet is bonded to the wood base with

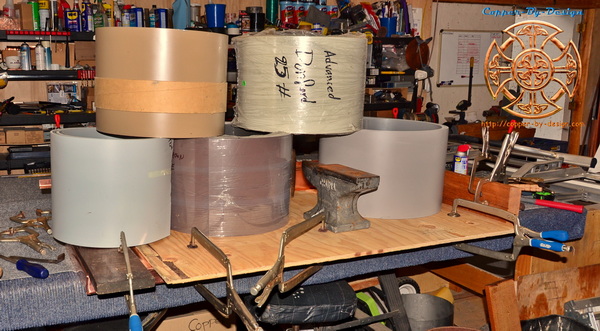

an expanding polyurethane glue, so it has a good solid feel. To do this I

have to rough sand the underside of the copper sheet before slathering glue

onto both surfaces. Then quickly place a sheet of plywood over the

copper with heavy weights on top with some clamps while the glue sets. As

shown here:

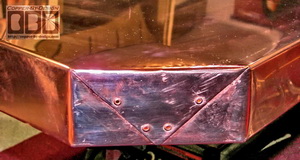

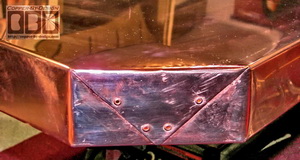

The copper is rough sanded underneath

to grip better to the expanding polyurethane glue, which bonds the copper

to the wood surface for a nice solid feel. Less tinny that way. The copper is carefully sealed at the

corners to be water tight and sanded smooth, so there are no sharp edges.

Examples? Examples?

These

first photos are of a bathroom set I had done for a local Client up on Council Crest

named Jeff Whitol in 2015, whom we had already done some copper gutter work for

previously. This was the finest compliment to be asked to do more work

for them such as this.

Customized?

When you need CBD to

build the wood counter top as well I use hardwood plywood

for more dent resistance and a better screw attachment than ordinary plywood or cheap particle board

commonly used.

We do our best to make these as seamless as possible, by

wrapping around the front edge of the counter tops and bending an upward

back-splash to keep any spills on top. The edges are sanded

smooth, so there are no exposed sharp metal edges. We cannot guarantee to

make these flawless, such as any custom hand made products, but we do our

best. Many even appreciate the rustic hand made aspect of our work.

Below is a few more photos this client had shared with us

after 10 years in service:

Cost?

These sort of project typically run

$100 per square foot for these covered with 32oz custom copper formed,

soldered, sanded, glued, and fine sanded. It can have a hammered texture or

patina added for and extra $20 sq'. If

you need us to build the wood foundation, I prefer to use a g=ood hardwood

plywood, instead of just particle board and it usually runs $30 sq' with solid

wood framework boards underneath that may be necessary to have a thicker outer

rim.

If you are

not local to the Portland, OR area then a custom wood crate, padding, and freight charges would apply.

I can use a thinner 20oz or 24oz

copper, but that would only save you about $5 to $8 per square foot and be

less than half as strudy. Given how most of what

you're paying for is design, labor, and in

some cases freight, using a thinner copper is not very

practical in the long run. My aim is not to up-sell you, but also explain

the best vlue for your $. I try to maintain my primary focus

on your 'long term satisfaction'.

Textured?

If you want a more rustic hammered copper look that adds $20

per sq' to

these projects.

Bold industrial looking rivets can also be added around

the edges for a rustic decorative element for $3 each. Bold industrial looking rivets can also be added around

the edges for a rustic decorative element for $3 each.

To

antique the copper would add another $20 sq' to these costs. I do not

recommend having us do that, since I cannot guarantee it will turn out just

the way you want, and I am not able to keep redoing this multible times to your

satisfaction at that cost. I host links on my Site Map to web site that go

into how you can patina the copper to get the look you want. If it does not

turn out the way you like it can be polished again to start over with

different chemicals. It could be quite a lengthy process to get just the

look you're after, or just let it tarnish naturally:

http://copper-by-design.com/links.htm#resources

Keep in mind the only way to keep this new penny look seen here

requires a clear lacquer coating, which would ruin the benefitial anti-fungal

properties of copper, and eventually become scratched up and peal after a while,

which would look

terrible. Keep in mind how any product is only as good as it weakest link. It could always be stripped off again and resealed, but that is not

a

simple process. Most Clients just let the raw copper age naturally, or have

it polished from time to time.

Below is an example of the 2 layers of 3/4"

marine grade hardwood plywood top for this vanity we covered with copper to

work with

this cute drop in sink.

Below is an example of hardwood plywood coffee table top covered with

a thinner 20oz copper and a set of curved copper pipes for adjustable legs.

As you can see the thinner copper does not lay as flat. You can see all 28

photos of this project on Facebook by clicking on this photo.

|