|

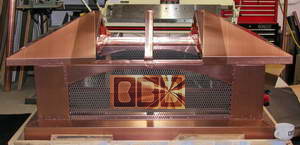

I also covered the roof

bracing a bit different

than I had done in the past; in stead of making the roof skin

with the seams over each

corner bend, I decided to cover each end with a singe seamless

piece that was a bit trickier to bend. Then draped a rectangular sheet

over these 2 ends. It is interesting how I had left the roof

line with this small jut out past the ends of the hipped roof line. I had intended to snip them and fold them down over the end

pieces, but sent the clients photos of it to see if they like it

wanted me to leave it that way. I let them know it would be easy for them to snip

and bend it down after it arrived, if they did not like that look after seeing it in person, so that's what we decided

to do.

Although, if I had intended

this look I would have extended it out a few inches further over

each end for a more noticeable appearance along with the ends folded straight down for added strength and to look more like a mini rake edge board.

As you will see below their house is a gable end designed roof

line that is a lot steeper, so it would have bee more suiting to

have made the roof of this chimney cap in this same style, but

that would have taken more copper and a larger shipping crate,

which would have added at least $500 to the cost.

Here is the break down:

$124 - 26.5# of wood

$295 - 7.5# of stainless steel screens, 14.75 sq' X $20

$640 - 32# of copper in the base and corner pieces

$620 - 31# of copper in the eaves and roof framework

$580 - 29# of copper in the roof skin

$350 - wood crate

$350 - shipping

$2,959 total - $2,000 paid

$959 balance due

The 92# divided by 1.25 = 73.6 square feet of copper X $25 = $1,840 for the copper portion.

Cost for

this project: $2,959 w/crate & shipping to a residence w/hydraulic

lift-gate service

Remarkably this was only $8 over what I had

quoted for a simpler low profile design

|