|

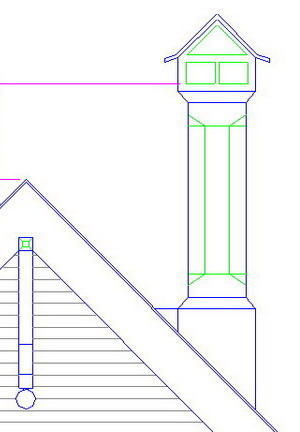

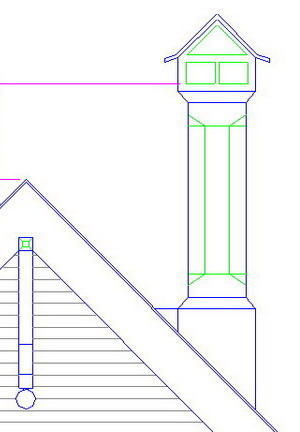

This custom copper chimney

projects was for our client named Gina Matury

who made this diagram on the left for Lake Prairie Homes, LLC at

9308 Chestnut Lane in Munster, IN 46321.

You can phone her at (219) 614-5144. She found our web site and was impressed

with our work, so she contacted us for a quote and we worked out

this collaborative design concept seen in

this diagram.

Her original thought

was just to replace the standard galvanized steel roof flange the

roofers used with copper. Then have me build this chimney cap made

for the top of the round flue pipe seen above. I suggested that

we could connect the two with a copper octagonal flue pipe. That

way the tarnished copper look would be consistent. She liked that

idea and was inspired to make this diagram. Later she mailed in

the 1/2 deposit of $1,500 on 2/07, once we had all the details worked

out.

|

|

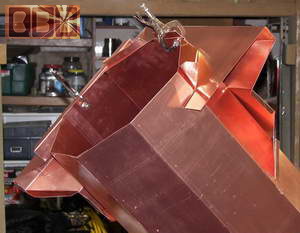

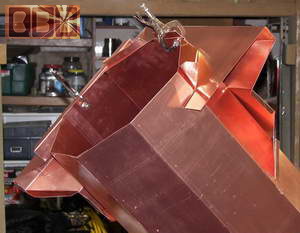

Most of the sheet stock we

work with is 20oz copper, but the base chamber here

is made from this 4' x 8' sheet of thicker 32oz copper sheet metal

for added strength to hold the flue pipe sturdy in high wind situations

w/o the need for support pipes or guy-wires.

The design took the entire sheet from edge to edge top and bottom.

I designed the whole

base chamber and roofing flange to be formed in one single piece

that is cut and bent to be as seamless as possible again for added

strength. Even if it made the fabrication a lot more difficult I

place more focus on strength and being water tight, and of course

so

it looks good as well. It is a bit scary to make sure I have thought

this through just right before cutting and bending this very expensive

sheet of copper.

|

|

|

|

|

It is built in 2 separate parts for easier installation.

This is also important for vertical alignment of the flue pipe; incase

the base does not set on the roof perfectly level once installed.

Then they will screw or rivet these together. The octagonal flue

pipe had to be made in 2 pieces, because of the large 14"

diameter. I made 6 of the 8 sides from one 36" wide sheet to be able to hide

the 2 seams toward the back of the flue. These days I work with

48" wide sheets to be able to form this with just a single seam

up the back.

|

|

The graduating transition

section just under the chimney cap is identical in shape and size

as the base transition below the flue pipe. After I built it I slid

it down over the flue pipe and riveted in place.

|

|

The 16 gauge stainless

steel screen also adds to the strength after it is riveted in place

behind the corner columns. This stainless steel screen is so hard

that it takes a $650 electric sheer just to cut it. It would break

the jaws of normal tin snips.

I added another brace

in the middle of the roof for added strength. The diagram called

for a 3" eave on all sides, but I made this with a 4" eave on the

gable ends to better shield out wind driven rains. The roof has

a matching 12/12 pitch angle with a 4/12 pitch kick at the bottom.

This meant I had to cut the vertical seam to make that bend, so

I used some of the scrap 32oz copper to make 4 braces to rivet behind

the seam to help hold that 4/12 section of roof up.

|

|

Here is the assembled

chimney out in the sun before getting crated up for it trip across

the country with David and Tia posing for the camera on a tripod

on a 10 second delay.

The cost breakdown:

$1,110 for the 55.5# final weight of

the base X $20

+ $1,101.60 for 55.08# upper section X

$20

+

$105 for 5.25 sq' of stainless steel spark arrest screen X $20 per sq'

= $2,316.60 subtotal

+ $800 for the crate and truck freight

to residential w/liftgate service

= $3,116.60 total

Note: She

was given a substantial discount for helping come up with this

original design that is a great addition to our web site

portfolio.

|

| Here it is

from different angles and getting crated for a safe journey: |

|

|

|

|

|

|

Here is a few shot of

the installation we got from Gina:

From: Gina Matury <gentuink@yahoo.c*m>

Date: Tue, 11 Dec 2007

Subject: Matury Project - Finally Photos!

Dear David:

We finally got the chimney up a few weeks

ago and I am finally getting around to sending you some photos.

If there hadn't been an ice storm here today that is keeping me

at home I wouldn't have had time yet!

I hope these photos are helpful. I will try

to get some better ones in the future. It really is beautiful and

I appreciate your work so much. Thanks again for all you've done.

Hope all is well with you and yours and that

you have a Merry Christmas, a happy holiday season and a great new

year!

Sincerely

Gina Matury

|