|

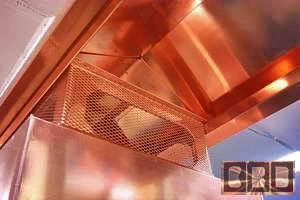

This shows the roof and three sides of the base formed, but not

folded.

The hood is only 19" wide, but took a 34" wide

x 49.25" long sheet of copper to make it. I had to remove one

of the 5 braces out of my metal bender to form this large hood just

right and this seamless.

The lower section design

has been drawn out on the copper on both the film side and the underside,

since there are several bends to be made in both direction. It

is careful work to bend the corners here so they are perfect right angles

before riveting them together. The cuts in the inside of the corners

are also tricky to calculate so it will fit together just right.

Our work table is 4' x 8'.

The sheet of copper shown come 10' long and 3 feet wide. It still has

the clear plastic film over one side that will be used for the outside

of this copper chimney cap to protect it from finger prints and scratches,

to be pealed off after installation. The cap angles need to be

carefully calculated so there are no errors or unexpected complications.

We have to think several steps ahead, like working out the problems

of a Rubixs Cube. If we are in error, we may ruin some very costly

copper material.

The hammer is used as a support inside the base

frame to help hold it up right, so the angles will be true 90 degrees.

It was still plenty wobbly.

|