|

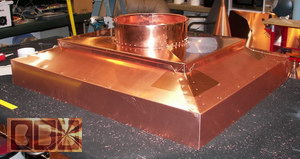

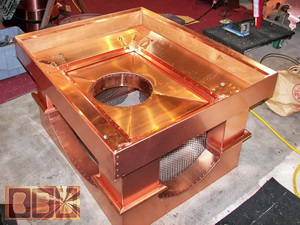

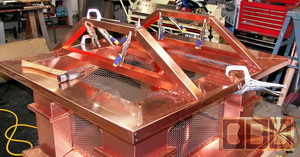

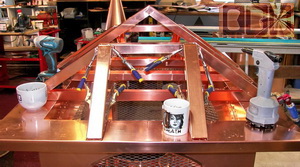

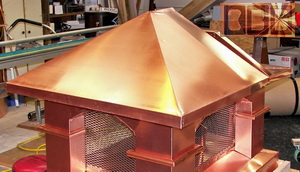

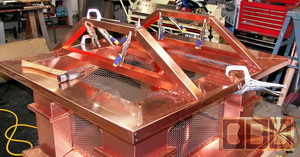

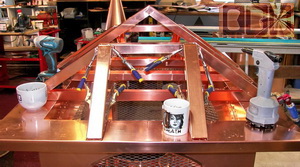

Here is the roof frame work being made and attached

before the roof skin can go on. Not being

perfectly square there is a ridge across the top.

Making the roof skin over

this is easy enough, but the best placement of the internal bracing

is more tricky. Unlike a house roof with 24" centers, I do not

want this to have any more than 12" between braces or hips. This

will give a very good support to the copper roof skin over them.

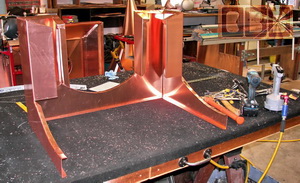

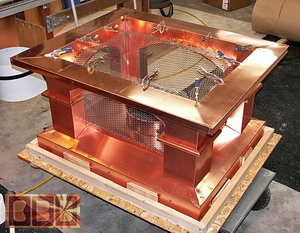

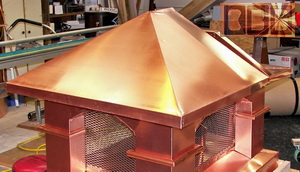

There are nearly 1,000 rivets

that hold this chimney cap together, but very few of them will be seen

from the outside. Just like with the auto makers, where they go to extremes

to hid the fasteners for aesthetics, yet still be just as strong.

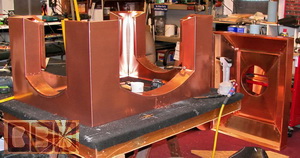

Since the amount

of copper was $787.80 over what I had quoted on 1/08/08 there was no

discounted final cost. I just needed to received the last check for

$1,100.20 so I could get this shipped off to their client's house? They

do prefer a business address, but that is not required.

Here is the final cost breakdown:

$ 350 wood crate

$ 350 shipping charge

$ 125 custom wood chimney cap saddle w/lag screws

$ 247.20 8# - 16ga stainless steel screen - 12.36 sq'

$ 135.83 13.6# Wood in the base - 13.583'

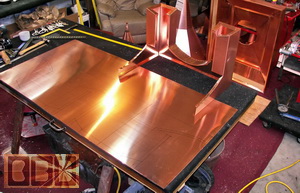

Copper content:

32.2# - copper base and pan - 25.76 sq'

29.6# - mid column section - 23.68 sq'

16# - eaves - 12.8 sq'

15# - roof bracing - 12 sq'

16.4# - back roof skin - 13.12 sq'

13# - front roof skin - 10.4 sq'

$ 2,932.80 - 122.2# of copper X .8

= 97.76 square feet X $30

+ $1,208.03 = $4,140.83 grand total.

Even without a contractors discount he got a really

good deal on this project. I normally do not like to work with

contractors, since they are more difficult to work with that most any

homeowner I have dealt with over the last decade, but this contractor

was easy to work with and I would recommend him. My aim

is to please the homeowner who is really buying our work, but I was

not able to contact them at all.

Cost for this project:

$3,304.20 w/shipping

Note: I under bid this project

by $836.63 mainly by not including the pan/collar and the eaves in that

quote, but I stuck the the price I had quoted him of course.

|