|

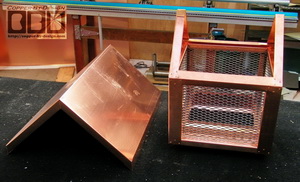

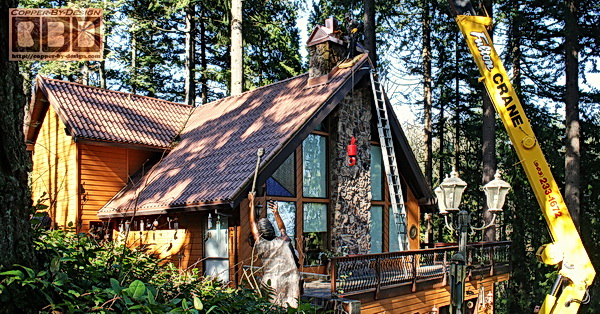

This copper chimney cap was designed and made for Bob and Lori Blair here in W.

Portland, Oregon. We also installed it over their stone

covered chimney of their house with the help of a hydraulic

crane. This house has an aluminum roof that

looks like a copper covered clay tile roof.

They first contacted me 1/5/10 and

we swiftly worked out the details of this project through

e-mails, and within a couple weeks they had sent in their 1/3

deposit of $950 to schedule this project in.

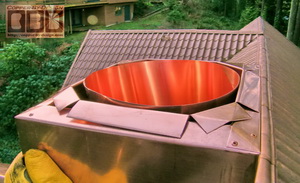

Here's what I found when first examining what was up there and had

failed to protect their home. The large chimney top was just covered with a flat sheet of

galvanized steel and had begun to rut and cause staining over

the rocks, as well as leaking into the house.

The steel pan was rusty, but what

concerned me more was the puddling on top from the flat surface

having caved in over the decades of snow loads and tree branches

coming down in wind storm and hitting this pan.

This cover was 77"

long X 31" wide. They originally wanted this built in just a

simplistic low profile style in order to save cost. Although,

just before I had a chance to begin work on it they said they

wanted to allow me artistic license and see where my inspiration

would lead me. I did my best not to get carried away with this

and kept them apprised of my thoughts for their approval and a

cost for these changes. The

design changes I suggested added $1,100 to the original quote,

but they were very pleased with the ideas I had to improve the

look and function of this cover.

As you can see they have some very nice

bronze sculptures adorning their property, so they wanted

something nice in copper to compliment their home, yet not cost

a fortune of course.

|