|

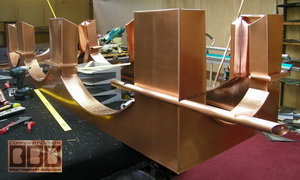

This set of 2 copper chimney caps were for Emil and Norma Bardana

in Lake Oswego, Oregon installed over their brick

chimneys. The larger chimney is over 121" long. They wanted these built in

my Tuscany arch style. I wish I had thought of this sooner for some of the 7' long chimney caps I had built. I could have at least made them with a double arch.

This is the largest Tuscany arch style copper chimney cap

project I've worked on to date. They first contacted me

6/12/09

and we swiftly worked out the details of this project through e-mails

and a personal visit in my workshop not long be fore we moved. I

came out to their house to check the measurements. Given the

length of over 10' long I came up with the idea to build this

one with more arches along the sides, so I did some elaborate photo

editing to make this image look like it had 3 arches instead of

just 1 to show them what this would look like.

I designed the roof line to resemble their

house with hipped 5/12 pitch, so this will look

more like what the architect might have designed for this house.

The client approved this design and were very pleased with the

results. We

discussed aesthetic options like adding 1" wider

roof that the base/skirt all around.

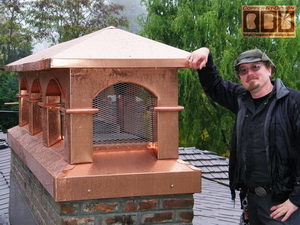

Here's the before and after photos of the installed

chimney caps.

|

|

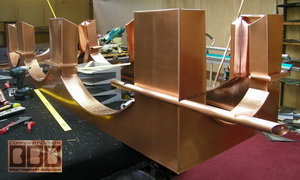

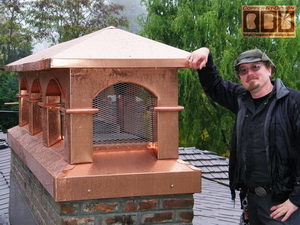

Here's the 8 pieces of Ipe hardwood support frame I need to build

inside the copper base that helps anchor this down in high

wind storms. I had to get a pair of 20' boards just to make sure I

could cut the long sides that are over 10' long. Each board has been

cut on 4 sides at an angle. The top and bottom were cut on my table

saw at a 30 degree angle and the ends were cut at a 45 degree angle

to miter them together. They will be positioned down low where it

should not suffer heat from the chimney.

Above right you can see the base/skirt for the smaller

chimney cap cut out and ready to be bent into shape to wrap over

the hardwood frame. Below shows the smaller base/skirt

assembled. The hardwood is glued inside the copper with the

expanding Gorilla glue. It is also held in place with long

rivets and I varnished the inside of the hardwood to keep it

dry.

Here's the long base/skirt getting the last

end assembled together. I have the clear plastic film removed

where the seams will overlap and where columns will go over this

structure.

|

|

This shows part of the arched columns being

laid out on the sheet of copper. There is a good deal of math

and geometry involved here, so it's all in the right proportion

and the bottom of the columns can sit right on the angled base.

The larger set needs to be made from 3 separate sheets of

copper, because it is so large. This also shows the 8 inside

liner of the arches formed for this 1 chimney cap.

This was a bit more tricky to build than I

had imagined being longer than my 8' work bench and very wabbly.

It took us a few days just to build this set of columns and

arches. Then there was the decorative piping to attach to each

column. Each corner column required a pipe that was about 30"

long. It took the majority of two 10' pipes for this one chimney

cap.

|

|

I cut and bent the 16 gauge stainless steel

screen to set into a channel along the inside rim of the bases.

These screens are what I get my hands lacerated on more than any

other aspect of my work, so it's important to cover all the

edges of this SS screen, so these are safe for anyone else after

these are complete. the SS screen is secured to the base through

the 3 layers of copper with dozens of longer rivets.

The column are attached to the base

with 36 SS screws and over 100 rivets. Then several hundred

rivets needed to inside to fasten the screen to the columns and

arches. These add a great deal of strength and stability to this

structure once attached. The sides of these arches no longer

will flex more than a 1/4" now.

|

|

Then the eaves are made and attached, which

adds a lot more strength to this long wall.

|

|

Then there is the roof support braces to make

and attach with SS screws and copper rivets. I believe this is a

very important detail that is not done by most any other sheet

metal shop from what I've seen. Not that we get a lot of snow

around here, but we did get about 15" last winter, so I do what

I can to prepare for the worst.

|

|

Then these were ready for the copper roof

skins to go over these braces and attach under the eaves.

|

|

When I got the final weights; the larger one was 317# and the smaller

chimney cap

was 137.6#. I had given them a huge discount for this

being such a large order and I was so excited to build this unique

triple arch version of my Tuscany style chimney cap. They were

so pleased with the work we did they contracted us to cover

their gazebo with new plywood and copper the next year.

The weights and cost

breakdown of these pieces are as follows.

Long Chimney Cap:

-

58.3# - wood frame inside the base/skirt -

26.25 ln'

-

21.2# - SS screen - 30.25 sq'

-

237.5# of copper sheet metal - 190 sq'

-

$6,650 - 190 sq' of copper X $35

-

+ $605 for 30.25 sq' of SS screens X

$20

-

+ $328.13 for 26.25 ln' of 5/4 x 6 hardwood boards

X $15

-

+ $400 for delivery and installation including crane

service

-

= $7,983.13 total

Smaller Chimney Cap:

-

29.2# - wood frame inside the base/skirt -

13.17 ln'

-

7.6# - SS screen -

10.83

sq'

-

100.8# of copper sheet metal - 80.64 sq'

-

$2,822.24 - 190 sq' of copper X $35

-

+ $216.60 for

10.83

sq' of SS screens X $20

-

+ $197.55 for

13.17

ln' of 5/4 x 6 hardwood boards X $15

-

+ $350 for delivery and installation including crane

service

-

= $3,586.55 total

$11,569.68 grand total - less $2,706.40

in discounts = $8,863.28 final cost

|

From: Emil Bardana

<bardanae@ohsu.e*u>

Date: Sat, 24 Oct 2009

Subject: Two Chimney caps for the Bardana

Residence in LO

Dear David: this is indeed unusual and

welcome news. Your integrity is appreciated and will be passed

along should anyone ever inquire. If you need to purchase some

protective mats to protect the shingles let me know. Also if you

could bring some wood to protect my stamped concrete that would

be appreciated. The caps look fantastic! Emil

From:

Copper-By-Design [mailto:quote@copper-by-design.c*m]

Sent: Saturday,

October 24

To:

Emil Bardana

Subject: Two Chimney caps for the Bardana Residence in LO

Good morning Emil and Norma,

I have some good news for

you. I got some weights this morning of what I have so far

without the roof skin on them; the larger one is 250# and the

smaller one is 113#. They both used a bit more screens than I

had predicted and the wood cost more than I had paid in the

past, but I did some calculations of what the roof skins should

require and I see the smaller one should be about 5 sq' less and

the larger chimney cap will be around 70 sq' less than

predicted, so you are looking at over $1k saving off the

original bid of $10,071.30, even with the added cost of the

crane and our participation with the installation. The balance

will be around $2,350, but I will not know for sure until we get

the roof skins finished. It may even be less. I imagine you are

not use to getting news like this form a contractor? |

|

Here is the installation photos we took while

it was being lifted up to the roof with this amazing crane

set-up. It was done by Fulton Crane here in Portland, Oregon Ph#

503-233-1672. I would highly recommend him. He arrived just

after 12 noon and was done before 12:30. It took us a lot longer

to peal off all the plastic film after they were installed.

He parked the big diesel truck crane in the

driveway and had a set of large hard rubber pads to place under

the side supports, so not to scratch up their textured driveway

surface. There was a good 70'

reach back over the roof just to get to the big chimney. It was

amazing how simple he made it seem while working blind with only

our hand signals to guide him.

It was a nice snug fit. Then we had to

scramble over to help lift the smaller chimney cap up to the

roof before synching this one down. Once they were in

place it was easy to check the level of them and just tighten the SS screws.

On the right is a shot of their back yard I had taken

from the roof near the long chimney cap.

|

Here is a few more shots of these chimney caps a year later. I

got a chance to take these when they asked me back to rebuild

their gazebo and cover with copper and add a cupola on top.

|